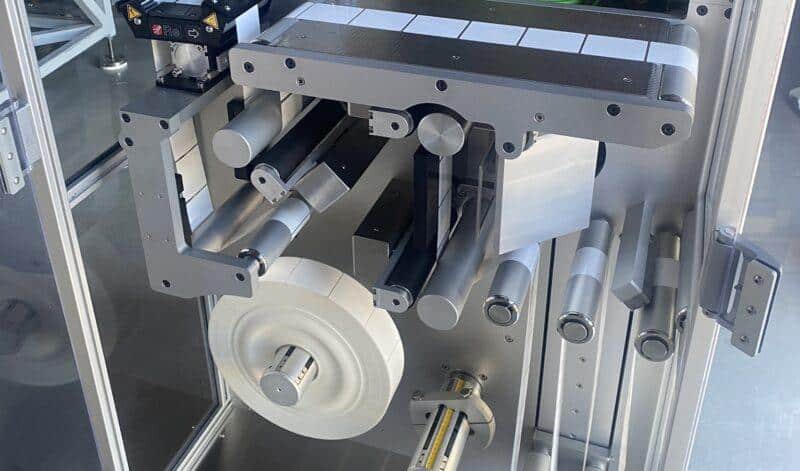

PPS PharmaJet digital inline printer

The first PPS PharmaJet inline digital printer has left PPS to go live with our customer, one of the world’s largest and most successful pharma companies. Hopefully, it’s the first of many more to come.

It has been a long and challenging development process to design and build the PPS PharmaJet. A solution with the most compact footprint of less than 1 m2, and still be able to print full-color labels in a print quality comparable to what you get from a dedicated label printing house.

We can deliver up to 1,000 fully serialized labels per minute in full color and with 100% vision inspection of both text and color matching. And it can be fitted into any labeling or packaging machine.

We offer a fully automated workflow where we can extract batch data, serialized data, and artwork data from any external source and automatically combine it into a label design. Both the printer and vision system are set up from the original PDF without any operator intervention.

What is inline digital printing?

Previously, digital printing technology in a compact form factor was not advanced enough to offer a sufficient print quality, compared to labels printed by dedicated printing houses. Due to that, it was only possible to print simple texts and elements in one color. But with inline digital printing, this is a thing of the past.

With our digital inline printer, we want to break with the widely used one-color, ribbon-based thermo-transfer print technology, which is only applicable for adding simple codes such as batch and expiry date. PPS PharmaJet inline printer can print in full color and allows you to print the complete product information inline, or even directly onto the product. The printing process takes place at the end of the production line, and you simply print the labels when you need them.

PharmaJet key points:

- It takes up less than 1 m2.

- It prints full-color labels of the highest print quality.

- It prints up to 1,000 fully serialized labels per minute.

- It has 100% vision inspection of both text and color matching.

- It can be fitted into any labeling or packaging line.

Benefits of inline digital printing

There are many benefits to using inline digital printing in the packaging process. Some of these are:

- Reduced complexity in internal processes (ordering, storing, and handling numerous different pre-printed labels).

- Reduced waste.

- Less QA resources for quality control and batch change-over.

- Reduced chance of error, as all labels are visually inspected just before application.

- Less storage space required.

- No change-over time.

- Higher packaging line utilization.

Further, inline digital printing also gives you the advantages of late-stage customization and the possibility of utilizing agile marketing campaigns and individualized information. Moreover, you get the ability to create thousands of labeling variations without adding complexity. As batch sizes continue to decrease and medicine becomes personalized, inline label printing is the true Industry 4.0 digital answer without adding complexity.

Click here for more information about inline printing and late-stage customization.

Or reach out to us if we should discuss how your packaging and labeling process can be improved.