Automation solution for Tojos Plast

Tojos Plast is a Swedish company with more than 70 years of experience in producing plastic items in customized solutions and various designs. As a wide range of solutions are offered in terms of material use, shapes, and colors, flexibility is key for the company.

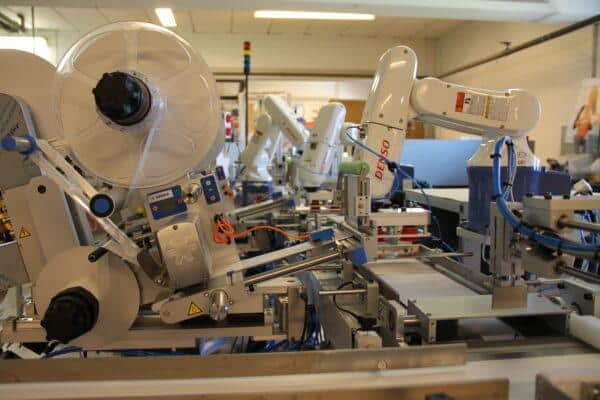

Five years ago, Tojos Plast contacted PPS for assistance with a new automation solution. They had a customer with unique needs and had therefore considered investing in a machine that could assemble and label multiple components in the same process. It was a completely new project, so everything had to be developed from scratch.

PPS suggested building a prototype to investigate the actual needs. The process was really good and a specialized solution was iteratively developed with the following steps:

- A molded box with contents is assembled

- Variable data is printed on a label

- The box is labeled on the front and back

- The boxes are stacked in sets of 5.

- A shipper box is erected

- 5 boxes are packed in each shipper box

- The shipper box is closed

During the work on the prototype, small issues were discovered early on and addressed. For example, small air bubbles formed under the labels. PPS made some changes to the design and it was eliminated. The result was that there were no errors or missing adjustments when the equipment was installed in production.

Full utilization

Along the way, PPS made suggestions for optimizing the process, utilizing the fact that the item was oriented and in a defined position in the robot’s gripper.

This implied that the process was expanded to include the ability to print batch numbers on the label, add an extra label, and pack the items in boxes.

These were all processes previously carried out manually by operators. Thereby one automation solution now solves multiple needs at the same time.

“With PPS, we found out what we actually needed. The process with a prototype worked really well. Both we and the customer could change things and we got the perfect solution.”

Per Mölleback

Tojos Plast

Flexible solution

Tojos Plast’s customer had changing needs. During the process, all parties became wiser about their needs and how these could best be automated. The customer saw the new opportunities in the setup developed by PPS and Tojos Plast.

PPS’s advice made it possible to develop a specialized but flexible solution that met all needs. At the same time, it can be changed and developed in the future.