The power of micronization in pharmaceutical production: unlocking enhanced formulations and drug delivery

In the dynamic world of pharmaceutical production, optimizing drug formulations and ensuring safe processing are paramount. Micronization, a technique that reduces particle size, has emerged as a game-changer in the industry.

This blog post explores the powerful benefits of micronization in pharmaceutical production, from improved formulations and enhanced drug delivery to safe and efficient processing. Additionally, we will delve into the innovative Frewitt Pinmill PMV-320, which combines micronization with advanced safety features to revolutionize the industry.

Enhancing formulations through micronization

Micronization plays a pivotal role in optimizing pharmaceutical formulations. By reducing particle size, it enables the creation of drug particles with a uniform distribution, enhancing formulation homogeneity. This improved consistency leads to better mixing with excipients, resulting in more accurate dosing, improved product quality, and increased patient compliance.

Improved bioavailability and solubility

A key advantage of micronization lies in its ability to enhance the bioavailability of pharmaceutical compounds. Many drugs suffer from poor solubility, which can hinder their absorption and effectiveness.

Micronization addresses this challenge by reducing particle size, increasing the surface area available for interaction with solvents and biological fluids. The result is improved dissolution rates, enhanced bioavailability, and optimized therapeutic outcomes for patients.

Advanced drug delivery systems

Micronization opens doors to the development of advanced drug delivery systems. By reducing particle size to the micron or even nanoscale, pharmaceutical scientists can create nanoparticles, nanosuspensions, and solid lipid nanoparticles.

These systems offer unique advantages such as:

- targeted drug delivery

- sustained release

- improved stability

Micronization empowers researchers to explore innovative approaches in drug delivery, leading to breakthroughs in personalized medicine and disease-specific treatments.

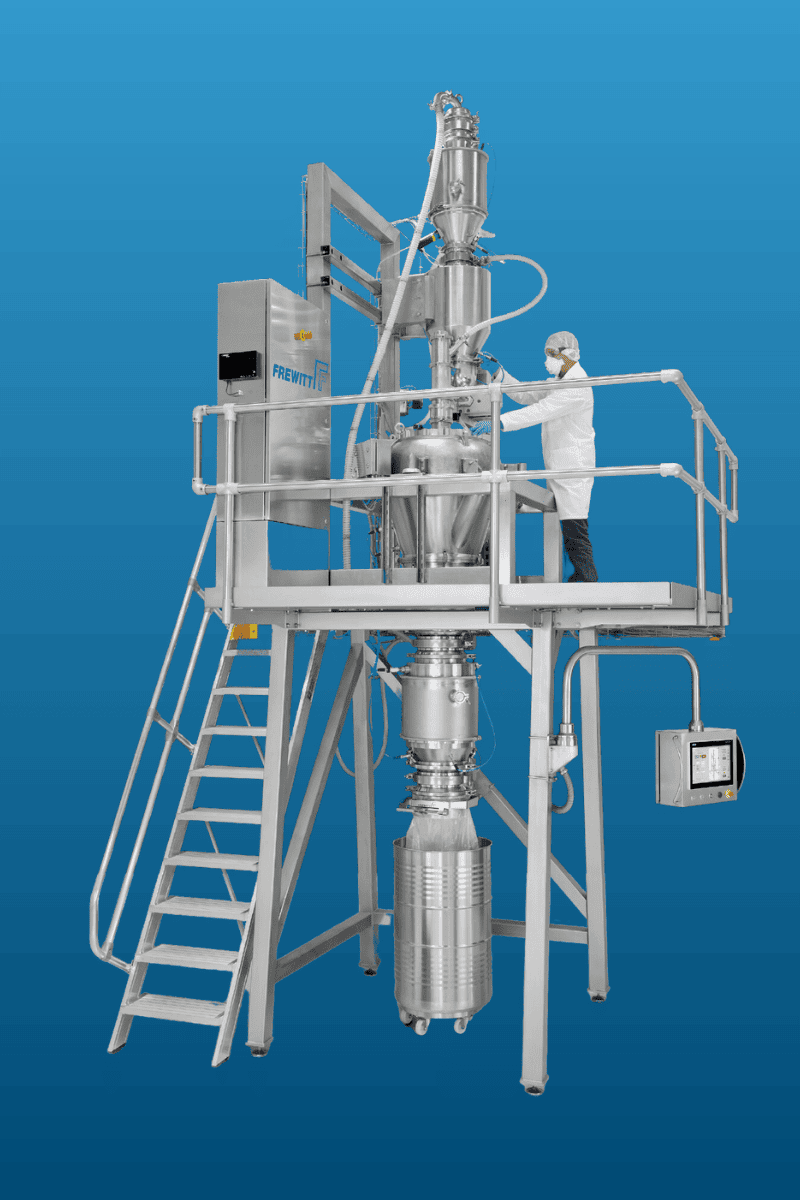

Safe and efficient processing with the Frewitt Pinmill PMV-320

In the pursuit of safe and efficient micronization, the Frewitt Pinmill PMV-320 stands out as an innovative solution conceived to revolutionize the process. It is designed as a single system that combines containment and micronization, with the safety of both operators and products in mind.

Compared to jet mills, pin mills offer a plug-and-play experience, eliminating the need for dedicated compressors, liquid nitrogen silos, and voluminous cyclone filters. They require significantly less process gas and are not as sensitive to high-pressure control, making them easier to operate and maintain.

The PMV-320 is a hig impact pin mill offering a particle size distribution range down to D 90 < 6 µm and a throughput up to 1,000 kg/hour.

Safety advantages

The PMV-320 operates under controlled vacuum conditions, eliminating the risk of explosion and protecting operators from exposure to high-potency or toxic substances. With an automatic integrity test before operation, it ensures a fully contained process that prioritizes operator safety.

Operating in a vacuum environment, the PMV-320 reduces process noise to a mere 69dB, creating a quieter and more comfortable work environment for operators. Additionally, the equipment requires a smaller, inline filtration surface compared to other mills, minimizing exposure during cleaning and filter change processes.

Compact design and cost efficiency

The PMV-320 boasts a compact assembly for easy integration into existing production lines, making it a cost-effective solution for pharmaceutical companies. Its scalability and adaptability to different floor plans and ATEX compatibility further enhance its versatility and cost-efficiency. The Pin Mill also benefits from a greatly reduced footprint.

User benefits of the Pinmill PMV-320

The powermill PMV-320 offers unprecedented performance and offers these user benefits:

- unique high impact mill, delivering a particle size distribution range down to D 90 < 6 µm

- throughput up to 1,000 kg/hour

- compatible for 0/20 ATEX – removal of traditional zone risks due to the process under vacuum

- process can be easily contained up to OEB 5

- rotor tip speed up to 250 m/s, depending on application

- elimination of noise

- extremely low process temperature elevation

- less product retention than competing technologies

- lowest consumables requirement for this type of process in the market

- compact assembly for easy in-line integration

- adaptable to mezzanine or multi-floor executions

- scalable to Frewitt Lab Scale / Pilot Scale Pin Mill systems

- best cost/value ratio in the market

Conclusion

Micronization plays a vital role in pharmaceutical production, offering advantages such as enhanced formulations, improved bioavailability, and advanced drug delivery systems. It offers numerous benefits for the pharmaceutical industry, contributing to the development of safer, more effective medications for patients.

Frewitt’s PinMill PMV-320 represents a significant leap forward in the micronization of pharmaceutical products. By combining simplicity, safety, and efficiency, this cutting-edge technology empowers medical companies to achieve optimal performance and protect their staff while ensuring the integrity of their APIs.

With its exceptional features and benefits, the PMV-320 sets a new standard for secure, fine milling processes. Embracing micronization and innovative equipment like the PMV-320, pharmaceutical companies can unlock new frontiers in drug development while prioritizing the safety and effectiveness of their products.

Do you want to learn more?

Are you interested in learning more about micronization, the PMW-320 or any other solution from Frewitt? Then please do not hesitate to contact us. You can fill out the form below or find all our contact details here.