Automation: gain a competitive edge in your pharmaceutical production

The business landscape is as dynamic as ever and the pharmaceutical industry is no exception. The ability to be flexible and cost effective is key to stay competitive, which has led to automation becoming a strategic imperative rather than just a mere trend.

While you may question the need for automation or struggle to envision its practical application, this article aims to shed light on the possibilities and advantages of implementing automation in pharmaceutical production. Our goal is that after reading this article you understand why automation should be part of your future strategy.

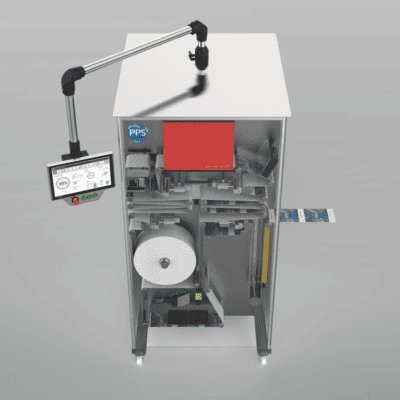

Automation solutions with robots can be in the form of simple pick and place robots, complete robotic lines, or anything in between. But even though robots are often thought to be the central element in automation, it does not have to include any robots at all. It can be any type of automated process e.g., this innovative digital inline printing solution. Either way, automation holds the key to unlocking new levels of efficiency, quality, and growth.

Automating pharmaceutical production

Streamlining Processes with Robotic Automation:

Robots have proven to be valuable assets in pharmaceutical production, revolutionizing mundane and repetitive tasks. By implementing robots for pick and place operations, companies can significantly reduce manual labor, minimize errors, and enhance productivity. Whether it’s transferring products between workstations or packaging and palletizing tasks, robots excel in precision and speed, leading to streamlined workflows and increased output.

Complete Robotic Lines for Advanced Automation:

For pharmaceutical companies looking to take automation to the next level, complete robotic lines offer comprehensive solutions. These lines integrate multiple robots and advanced technologies to automate complex processes, from product assembly and inspection to labeling and packaging. By synchronizing the actions of various robots, manufacturers can achieve seamless and efficient production, ensuring consistent quality while meeting demanding production requirements.

Digital Inline Printing: An Innovative Automation Solution:

One exciting automation solution gaining traction in the pharmaceutical industry is digital inline printing of labels developed by PPS. This technology allows for the on-demand printing of variable data directly on products or packaging materials during the production process. With high-resolution printing capabilities and flexible customization options, digital inline printing enables enhanced product traceability, serialization, and anti-counterfeiting measures. Additionally, it eliminates the need for separate labeling processes, reducing costs and increasing efficiency.

Advantages of Automation in Pharmaceutical Production

- Improved Efficiency: Automation reduces manual labor, minimizes errors, and optimizes production cycles, leading to increased throughput and reduced downtime.

- Enhanced Quality Control: Automated systems ensure consistent product quality, minimize deviations, and facilitate compliance with regulatory standards.

- Cost Savings: By streamlining processes, automation reduces labor costs, minimizes material waste, and improves overall resource utilization.

- Scalability and Flexibility: Automation solutions can be tailored to accommodate changing production demands, allowing companies to scale their operations efficiently.

- Increased Productivity: By delegating repetitive tasks to machines, automation frees up human resources, enabling them to focus on more critical activities, such as research and development.

- Enhanced Safety: Automation helps minimize human intervention in potentially hazardous tasks, promoting a safer working environment for employees.

Conclusion

Staying at the forefront of technological advancements is key to success in the pharmaceutical industry. Automation presents a multitude of possibilities and advantages, from improved efficiency and quality control to cost savings and increased productivity.

Whether it’s the implementation of robots for specific tasks, the integration of complete robotic lines, or shifting to digital inline printing, embracing automation brings pharmaceutical companies a competitive edge.

To know more about the possibilities of automation, you can get more information by following these links:

Case example of a palletizing solution that we offer as a ‘Plug-and-Play’ complete package starting from 425.000 dkk.

Digital inline label printing developed by PPS.

Let’s talk

For more information on the specific needs and possibilities for your production, please contact us and we will guide you in the optimal solutions for your production environment.

We are specialized in individually designed solutions, but also offers several standard models. No matter which one, PPS can deliver the complete solution.