Inline digital printing

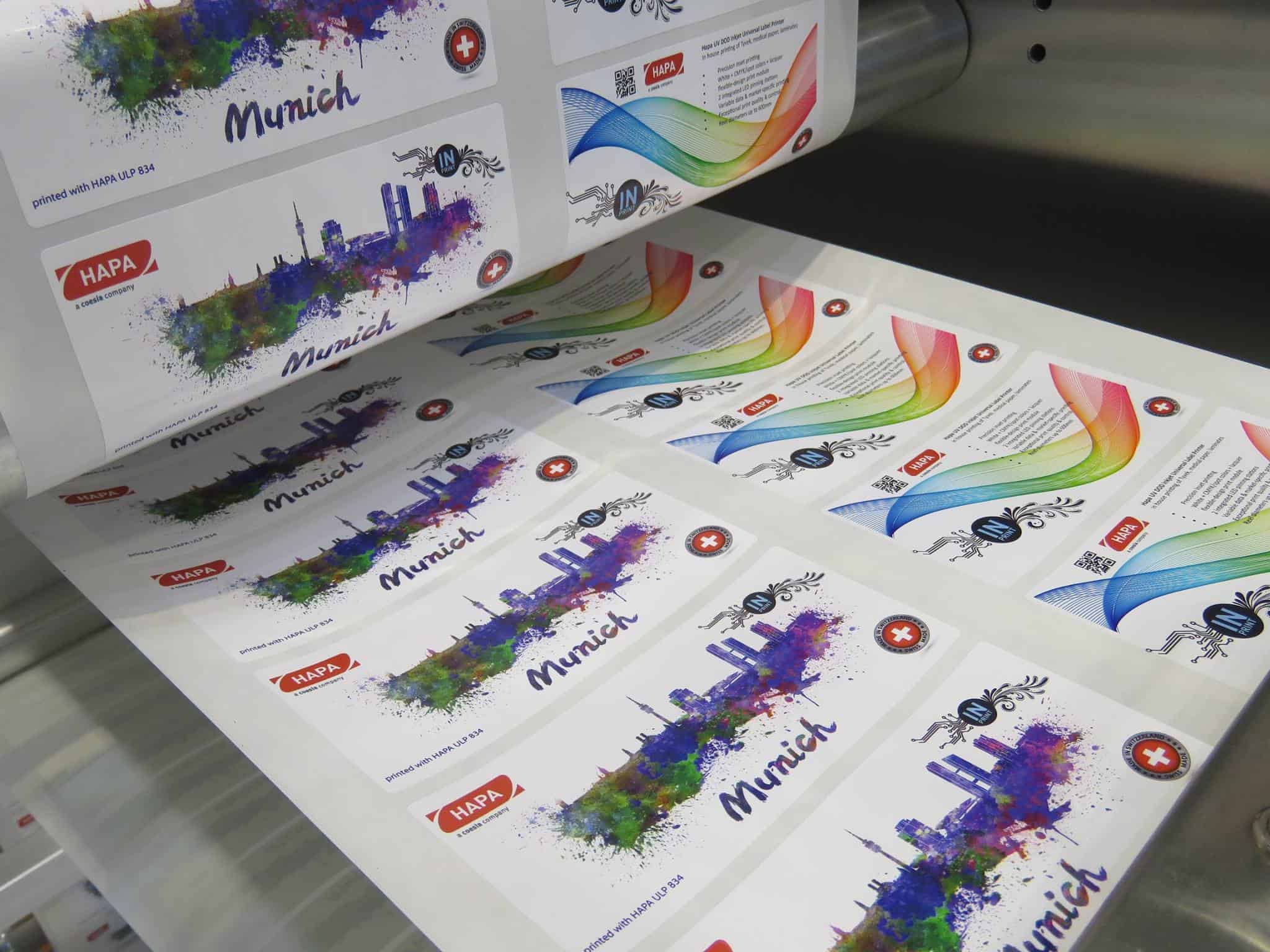

For retail and wholesale alike, labeling is a common thread with all types of packaging. Labeling allows for everything from product identification to providing ingredient or warning information, as well as offering products a consistent brand identity. Inline digital printing allows you to print this information on your packaging without the need for additional processes before or after the packaging stage.

Read on to learn more about inline digital printing and how this technology is revolutionizing packaging processes across industries. You can also read more about our own PPS digital inline printing solution here.

What is inline digital printing?

Previously, digital printing technology in a compact form factor was not advanced enough to offer a sufficient print quality, compared to labels printed by dedicated printing houses. Companies selling the same product to numerous different countries must comply with the requirements for packaging, labeling, and product information of each country. They must also provide all relevant information for the product in the official language of each respective country.

Until recently, this made the final stage of packaging products unnecessarily complicated and time consuming. The packaging of each product variant required individually preprinted labels with the variable data corresponding to the requirements for each country, printed by an old fashioned and low-quality ribbon-based print technology. Not only did this decrease the efficiency of packaging lines; it also caused the price per unit to rise.

With inline digital printing, these inefficient processes are a thing of the past. An inline digital printer allows you to print the complete product information directly onto your packaging. This means that you effectively avoid the need for having your packaging preprinted, and you must only store white packaging material in the required sizes. There is no need for thousands of pre-printed label variants on stock or buying more labels than you need to avoid running out – you simply print the labels when you need them.

Benefits of inline digital printing

There are many benefits to using inline digital printing in the packaging processes. Some of these include:

- Lower unit prices

- Reduced waste

- Less storage space required

- No change-over time

- Higher packaging line utilization

Further, inline digital printing also gives you the advantages of late-stage customization and the possibility of utilizing agile marketing campaigns and individualized information, as well as the ability to create thousands of labeling variations.

Late-stage customization

With inline digital printing you can go from a newly designed label to printed product in a matter of minutes. This allows you to completely change your packaging process and postpone the customization of your product until later in the process. Late-stage customization basically means that you pack your product in neutral packaging material, without specific market data, as this is added as an inline print process during the shipping process. By doing this, you reduce your inventory levels since you do not need to stock as many product variants, and you become more agile in responding to market demands.

This creates a much more flexible packaging process, giving you the ability to:

- Test and adjust packaging designs directly on site and print as soon as the final approval is received.

- Bulk-order blank packages at a reduced cost and store them until needed.

- Add current packaging or labeling customization during the filling stage.

- Turn out products more quickly, as you will not have to wait for new packaging to be printed.

Late-stage customization also helps to reduce waste, as you will not have to bulk-order packaging with preprinted information that may expire before the product sells. This waste reduction also contributes to reducing the environmental impact of the packaging process.

Agile marketing campaigns and personalization

Inline digital printing allows you to print advertising, promotional designs and marketing messages directly onto your packaging. This enables you to utilize your packaging as a primary marketing tool and adjust as different promotions go into effect.

Further, inline digital printing also allows you to improve your marketing campaigns with completely personalized products, without any additional costs or change-over time, as you can make each print unique.

Labeling variations

As mentioned above, companies selling the same product to numerous different markets must comply with the requirements for packaging, labeling, and product information of each country.

In some industries, e.g., the pharmaceutical industry, this includes printing a wide range of data such as batch numbers and expiration dates, as well as warning labels, product information, and instructions in a wide range of languages. These variations are printed on the product itself as well as the packaging the product arrives in. Inline digital printing makes it possible to make these changes with no additional steps and without disrupting the supply chain.

Find your digital printing solution at PPS

At PPS, we offer several digital printing and labeling solutions for printing relevant information on a wide range of surfaces. We can offer everything from simple manual label applicators with a one-color printer, to a high-speed full-color inline print and labelling solution tailored to your specific process or built into your existing packaging line.

We also offer a long list of services, including installation and renovation of existing equipment, training of technical personnel, as well as delivery of spare parts and consumables directly to our customers.

Contact us for more information about our inline digital printing solutions.