Meet us at Achema

Achema is the place to be if you want to experience the latest in technology that transforms tomorrow. Some of the key topics are:

- small batch production

- flexible production

- sustainability

- digitalisation

Top renowned brands exhibit at the show, including several of our business partners: IMA, Hapa, Müller, Pharma Technology, GUK, and Sepha.

To get the most out of your visit, please set up an appointment with us and we will show you the very best from our business partners. Our sales team is present at the entire show and they are happy to show you around.

👉 Søren Pedersen +45 26187500 – sp@pps.as

👉 Sonny Bue Olsen +45 29291666 – sbo@pps.as

👉 Mikael Ulbl +46 701447450 – mu@pps.as

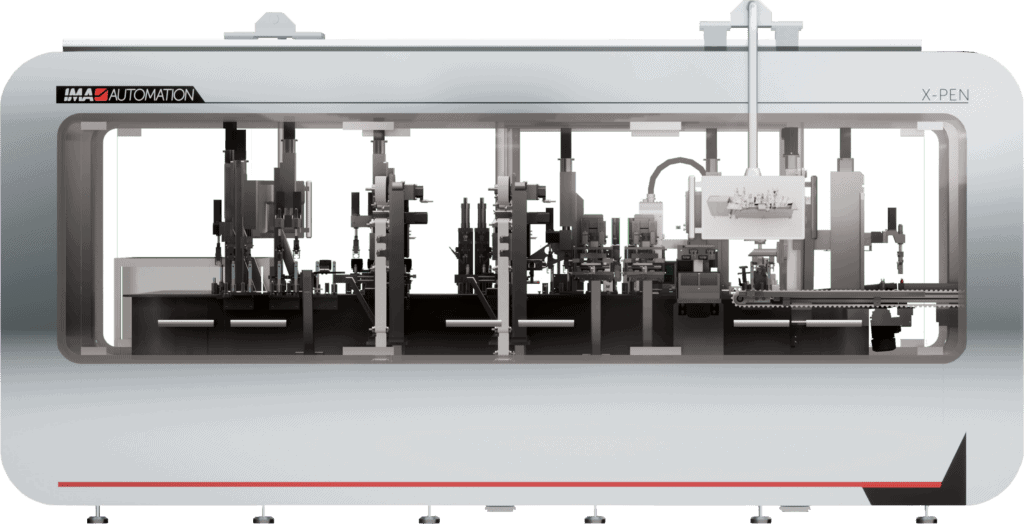

IMA Automation X-PEN assembly

X-PEN is the IMA Automation standard modular platform for final assembly of injectables and it offers the latest technologies, labelling as standard, quick time-to-market, compact design, and a fast ROI.

The X-PEN is based on a Linear Magnetic Transport System (LMTS) and uses state-of-the-art technology to assemble pens, autoinjectors, and safety syringes.

IMA GIANT 5 blister packaging and A96 cartoning

The combination of the blister line GIANT5 and the cartoning solution A96 provides an unparalleled level of flexibility, speed, and compactness. It is specifically designed for large batch production and handles fast and frequent changeovers effortlessly.

GIANT5-A96 can process any product type, including fragile tablets, thanks to the Sombrero blister feeding system. It can produce up to 1,300 blisters/min and 500 cartons/min and machine functions, product handling, and packaging capabilities, are not affected by high speeds.

IMA aseptic fill-finish processing

Exploiting the enhanced performance of advanced robotics, INJECTA 36 raises the bar for the high-speed processing of RTU components.

INJECTA 36 is a fine-tuned solution that enhances aseptic fill-finish capabilities and maximizes processing line performance. It handles up to 36,000 RTU components per hour.

It allows superior processing accuracy with 100% IPC, ensures innate flexibility, and satisfies the growing need to reduce the time to market for vaccines and key pharmaceuticals.

IMA TILE-X small-batch filling line

The TILE-X is IMA Life’s ground-breaking innovation in fill-finish processing for small-batch production.

It is suitable for advanced biopharmaceuticals such as ATMPs and cell & gene therapy products.

TILE-X presents a modular design handling RTU components, where movement is managed using magnetic levitation technologies to ensure precise processing, zero friction, and a 100% gloveless solution.

IMA ADAPTA 50 capsule filler

ADAPTA 50 combines all the best of IMA Active competences in capsule filling.

It features innovative technical solutions to manage complex solid dosage forms such as product combinations in hard gelatine capsules or powder micro-dosing for Dry Powder Inhalers.

The result is a unique machine that further underscores the hallmarks of the acknowledged ADAPTA capsule fillers.

IMA AQUARIA parts washer

Powerful yet essential, effective, and smart.

AQUARIA is IMA Active’s new component washer, maximising the washing chamber volume while minimising the size of the machine.

AQUARIA offers a variety of configurations to keep consumption under control and ensure greater efficiency and respect for the environment. Simplified washing concepts based on intelligent design together with GMP-compliance enable AQUARIA to fully respond to industry requirements.

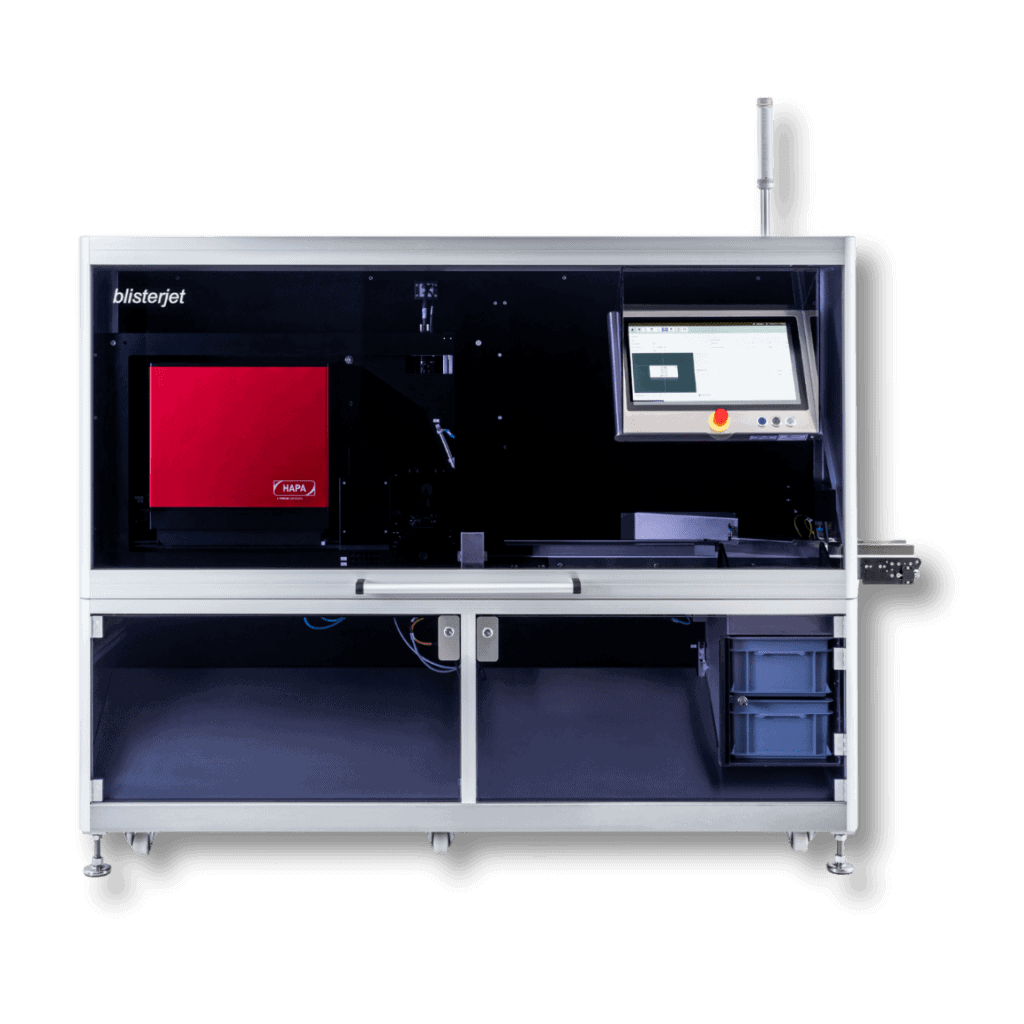

HAPA blisterjet agile for late-stage customization

The blisterjet agile is the most cost-efficient, versatile, and digital late-stage customization solution for sealed pharmaceutical blisters.

This solution enables the digital transformation of the graphics chain for blister packing lines. It combines new printhead technology for highly efficient artwork printing in any spot colour or full color artwork (CMYK) and variable data printing in monochrome.

The vision inspection system is part of the system, controlling the print quality at a high level.

Let’s meet at Achema

We look forward to an inspiring week in Frankfurt and to meet and greet with our customers and partners.

Don’t hesitate to get in touch with us for a presentation of any solution from our business partners or to have a coffee and a talk.

👉 Søren Pedersen +45 26187500 – sp@pps.as

👉 Sonny Bue Olsen +45 29291666 – sbo@pps.as

👉 Mikael Ulbl +46 701447450 – mu@pps.as

You will find us and our partners here: