IMA packing and end-of-line

PPS supplies a number of different packing and end-of-line equipment from IMA .

Packing and end-of-line equipment covers horizontal and vertical cartoners, case packers, shrink wrapping machines, stretch-banding machines, and palletizers, including integrated systems and tailored solutions. PPS also offers all round labeling solutions, including automatic label applicator, that labels in a safe and secure manner.

Moreover, we offer customized and/or automation solutions matched to individual customer requirements. Please contact us for more information.

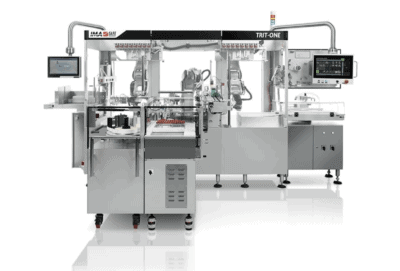

IMA TRIT-ONE Robotised Cartoning Solution

IMA is changing the approach to healthcare with their innovative cartoning solution. The next step in the fight to cure rare and aggressive diseases is to develop high-efficiency drugs based on individual patients’ DNA.

The robotised cartoning solution is designed to handle any kind of product (blisters, syringes, sachets, etc) and has a 1-product-batch option. Moreover, TRIT-ONE offers product traceability and validation of the entire packaging process.

- 1-product-batch option

- Gentle, precise product handling

- Huge carton configuration flexibility

IMA AF60 Over wrapping machine

Latest-generation, servo driven, technological solutions make the AF60 a premium over wrapper for collated material, easy-to-operate and able to process cartons at very high speeds despite its remarkably compact footprint.

IMA A100 Over wrapping machine

Designed and built to automatically wrap cartons, trays, bundles and other parallelepiped products, the A100 uses cellophane, PVC, PP and all reel-fed, heat-sealable film types, and with its entirely mechanical movements, enjoys minimal need for maintenance.

IMA HYWRAP20 High speed overwrapping machine

Designed to maximize efficiency for high-speed productivity and excellent packaging. The new high speed overwrapping machine ensures ease of use and total access to all machine operations running film and paper.

IMA MS560 Stretch banding and shrink wrapping machine

Designed to bundle bottles or cartoned bottles and shrink wrap them with PE film in the extremely compact T600 tunnel, the MS560 ensures time-saving efficiency, ergonomics, ease-of-use and top quality execution.

IMA MS260 SERIES Stretch banding and shrink wrapping

Designed to offer high speed production, simple operation and a compact footprint, the MS260 comes in different versions according to specific needs. High speed stacking, carton tilting and a shrink tunnel can be integrated into this high-performance unit.

IMA MS280 SERIES Stretch banding and shrink wrapping machine

Built to match the performance of high-speed production lines, the MS280 attains impressive speeds thanks to its refined servo driven technology. Cartons are stacked in multiple layers and when handling bottled items, these are collected in several rows.

IMA CP18/CP28 Side loading case packing machine

Side loading case packers suited to packaging individual or bundled cartons into pre-glued RS cases. They are compact, accessible and enable simple, tool-free size changeover.

IMA CPH2 Side loading case packing machine

Medium speed case packer designed to handle the widest range of products and materials used in pharmaceutical, personal care and food industries. Fully automatic side loading case packer designed to satisfy all of your current and future case packing requirements.

IMA CP38 Side loading case packing machine

Specifically designed to handle loose or bundled cartons, the CP38 is a high-speed, side-loading case packer benefiting from operator-friendly cantilever design ensuring complete accessibility and easy cleaning.

IMA CP50 Side loading case packing machine

The CP50 is a high speed side loading case packing machine specifically designed to handle small dimensioned cases at high speed, benefiting from operator-friendly cantilever design ensuring complete accessibility and easy cleaning.

All the parts on CP50 can be reached from the operator’s side without having to walk to the opposite side to reach carton stacking unit area. In order to be as “operator friendly” as possible the case erecting mechanism of this machine has been designed to ensure extremely low positioning of the horizontal case magazine. This guarantees long autonomy.

As dictated by the most modern requirements of technology, the CP50 is entirely driven by servo-motors which means dedicated strokes and motions for each specific application. Servo technology and innovative solutions allow the machine to achieve a very high speed (up to 50 cases/min.) with smooth product handling and compact footprint.

IMA CPV15 Top loading case packing machine

A medium-output, top loading case packer for loose or bundled products, the CPV15 has been conceived to assure maximum ergonomics for operating staff and guarantee smooth handling even for unusually shaped products thanks to servo technology.

In order to be as operator-friendly as possible, the case erecting mechanism is designed to ensure low positioning of the horizontal case magazine, which also ensures increased autonomy. Machine parts can be reached without operators needing to move from one side of the machine to the other.

The infeed system is equipped with worm screws (for loose products) for the correct orientation of the containers and a comb which moves sideways to collate the products.

- Cantilever design enables great accessibility and easy cleaning.

- Cases positively erected and moved to the closing section by a set of reciprocating lugs.

- Cases can be closed with adhesive tape or with hot-melt glue.

IMA CPV20 Top loading case packing machine

A modular top loading case packer for loose or bundled products, the CPV20 has been designed to offer unrivaled flexibility. Working at medium-high speed, it can easily incorporate special modules for specific requirements.

Attention to ergonomics and undeniable flexibility are the primary characteristics of this case packer. A top-rate solution for the pharmaceutical, food and cosmetic industries, the CPV20 handles a variety of bottle shapes, cartons and bags and is suited to the integration of Track & Trace systems, ensuring maximum accuracy and control. Up to 20 cases/minute can be processed, offering excellent productivity.

Great emphasis has been given to the machine accessibility, easy cleaning and ergonomic position of all its components. In order to be as “operator friendly” as possible the case erecting mechanism is designed to ensure a low positioning of the horizontal case magazine which also gives greater autonomy.

- Specific infeed systems to handle a wide variety of product shapes: bundled or loose bottles and single cartons.

- Modular design for the integration of special modules for different requirements: booklet feeder, inspection cameras.

- Cantilever design for complete accessibility and easy cleaning. Ergonomic position of all components.

IMA MMP400 Wrap around case packing machine

The MMP400 is a modular multi-packer built to pack individual or bundled products into cases, display boxes or trays. The machine has been designed for the efficient handling of all shapes and sizes, even if they are unstable or critical to run at high speed.

Built to pack individual or bundled products into cases, display boxes or trays starting from flat blanks, the MMP400 wrap-around case packer features servo technology enabling speeds of up to 30 cases/minute and extremely smooth handling.

Ergonomically positioned components help to significantly improve operator intervention and thanks to a newly designed case erection mechanism, the horizontal case magazine is as low as possible to achieve increased autonomy. Cases are erected and held in position on two sides during loading.

- Cantilever design for optimum accessibility and easy cleaning.

- New 830 mm height case magazine for easy loading of cases.

- Machine fully servo equipped.

IMA RP2/RP4 Stand alone or integrated palletizing

Reduced dimensions of the palletizing section and flexible palletizing options, in line with real market needs; these aspects characterize the RP2/RP4 palletizers, equipped with a 6-axis robot capable of absorbing and working at high speed.

Built to deliver maximum productivity and efficiency, these latest-generation palletizing solutions offer exceptional flexibility. Based around a 6-axis robot which picks up incoming cases, ink-jet printing and labeling or weighing them, everything is carried out efficiently.

Cases are then placed on the pallet according to pre-set patterns memorized by the operator. Modular design allows for customization of the palletizing section, whose dimensions are kept to a minimum.

- Equipped with their own electrical cabinet they can be easily integrated with any case packing solution.

- Simplicity in handling single or multiple cases even at high speed.

- Easy and fast assembling. RP2/RP4 structure is made of a special frame that takes a short time to be installed. The frames are provided already pre-assembled.

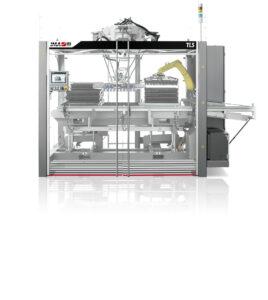

IMA TLS Top loading system

TLS is a robotic system able to load/unload products from/to trays. This machine has been devised to enhance production line performance with great flexibility of functions, product handling and layout.

- PLC unit interacts with robot processor for straightforward operation.

- Operator interface for fast changeover procedures and assistance with diagnostics.

- Transparent guards interlocked with safety switches.

PPS Service & Aftersales

Uniquely for the industry PPS has its own service department, which is of great benefit to our customers. PPS service department has specially trained technicians with the highest expertise and experience. We offer a long list of services, including:

- Installation and renovation of existing equipment.

- Design of complete solutions; everything from the requirements specifications and logistics, to execution and validation.

- Competent feedback on automation solutions or other type of production optimization.

- Installing and/or moving entire production or packaging lines.

- Training of technical personnel and operators in optimal use of the installed equipment.

- Tailor-made service and aftersales agreements for ongoing maintenance as well as assistance in case of breakdown.

In addition, PPS delivers spare parts and consumables directly to our customers from own stock. Having our own stock ensures fast and efficient delivery, which minimizes any production downtime for our customers.

If you want to know more about our service department, please contact us directly or get more information here.