IMA Tablet counter

PPS and IMA supply a wide range of tablet counters for many different products. Tablet counters can work as stand-alone units or be integrated into complete packaging lines.

We also offer bottle unscramblers, as well as other complementary equipment, such as bottle erectors, bottle cleaners, screw capping, press-on capping, and more. Please contact us for more information.

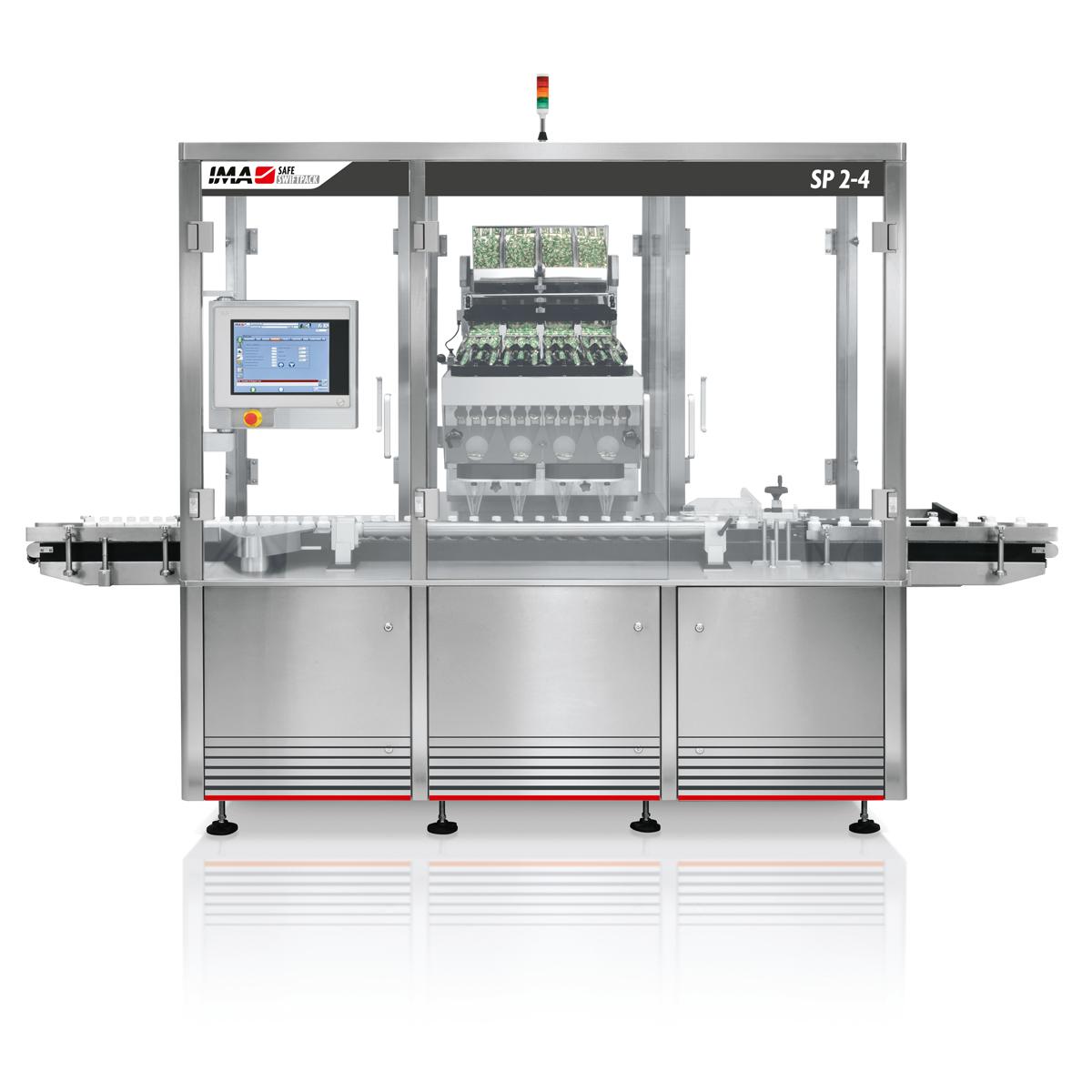

IMA SWIFTPHARM 2 Electronic tablet counters

IMA SWIFTPHARM 2 is a versatile counting/filling system to pack a variety of products accurately at high speed, and requires few or no change parts to allow maximum productivity.

SWIFTPHARM 2 Series is a pharmaceutical grade electronic tablet counter, with a positive transport of the bottles, available in two configurations according to the speed needed: SWIFTPHARM 2-4 with one counting head and SWIFTPHARM 2-8 with two counting heads.

With this Series the highest level of count accuracy is granted by different counting technologies solutions available (Optical sensor and E.F.S. – Electronical field sensor) which are able to work also in difficult conditions. Moreover, SWIFTPHARM 2 is extremely easy to clean and its integrated guards design allows a perfect integration of containment solution if needed.

- No additional space is required at the back of the counter for cleaning procedure.

- The simpler layout allows a simpler cleaning procedure and reduce the down time.

- Integrated guard design lending towards higher levels for product isolation.

IMA TB4S Electronic tablet counter

The TB4s is a stainless steel electronic tablet counter that offers an extremely versatile and accurate method of counting of most shapes of tablet, capsule, dragee hard and soft gelatine capsules.

The IMA TB4s operates in batches of 1 to 10,000.

The machine is highly adjustable, quick to set up and clean with excellent GMP design. With over 50 years experience and thousands of installations worldwide, IMA is the clear leader in electronic tablet counting.

- Contact parts manufactured in stainless steel.

- Accurate counting.

- Repeatable accuracy.

IMA ILS-1 In line sorter – Linear unscrambler

ILS-1 is a new linear unscrambler with integrated bulk hopper, ionized air rinse and inspection for highly efficient bottle feeding.

Designed for maximum flexibility, the ILS-1 can handle a wide range of bottles and can be changed over quickly without any tools or change parts. A fully interlocked enclosure provides operator safety and very low noise emission while ensuring complete visibility of the entire operation.

The integrated inspection / rejection system ensures that any upside down or fallen bottles are automatically returned to the bulk hopper. This eliminates the need for the operator to recycle the bottles and provides maximum efficiency.

The machine can be installed in new or existing packaging lines and adapts to most conveyor designs.

- GMP design with fully interlocked guarding

- Very low noise

- Integrated 525 liter (18.5 ft³) bulk hopper with ergonomic loading height

IMA ROTARY UNSCRAMBLER Automatic bottle unscrambler

This Series has been designed to handle a wide range of plastic bottles and is available in 3 sizes dependent upon output. This fully guarded machine is constructed to meet the latest requirements for GMP.

Bottles are loaded randomly into the large covered hopper from where they are raised into the starwheel by the flighted infeed. The starwheel separates the bottles, loading them into pockets. Each container is then transported to a secondary starwheel for placement onto a conveyor, upside down bottles are ejected using compressed air. As an integrated system the rotary unscrambler can be synchronized to line outputs and container backup controls will start and stop the system on demand.

With few quick release change parts the system can be easily changed over to different bottle formats in 5 minutes without the use of tools.

- Large storage hopper.

- Stainless steel/acrylic construction.

- Safety guarding.

PPS Service & Aftersales

Uniquely for the industry PPS has its own service department, which is of great benefit to our customers. PPS service department has specially trained technicians with the highest expertise and experience. We offer a long list of services, including:

- Installation and renovation of existing equipment.

- Design of complete solutions; everything from the requirements specifications and logistics, to execution and validation.

- Competent feedback on automation solutions or other type of production optimization.

- Installing and/or moving entire production or packaging lines.

- Training of technical personnel and operators in optimal use of the installed equipment.

- Tailor-made service and aftersales agreements for ongoing maintenance as well as assistance in case of breakdown.

In addition, PPS delivers spare parts and consumables directly to our customers from own stock. Having our own stock ensures fast and efficient delivery, which minimizes any production downtime for our customers.

If you want to know more about our service department, please contact us directly or get more information here.

IMA Tablet counter

PPS and IMA supply a wide range of tablet counters for many different products. Tablet counters can work as stand-alone units or be integrated into complete packaging lines.

We also offer bottle unscramblers, as well as other complementary equipment, such as bottle erectors, bottle cleaners, screw capping, press-on capping, and more. Please contact us for more information.

IMA SWIFTPHARM 2 Electronic tablet counters

IMA SWIFTPHARM 2 is a versatile counting/filling system to pack a variety of products accurately at high speed, and requires few or no change parts to allow maximum productivity.

SWIFTPHARM 2 Series is a pharmaceutical grade electronic tablet counter, with a positive transport of the bottles, available in two configurations according to the speed needed: SWIFTPHARM 2-4 with one counting head and SWIFTPHARM 2-8 with two counting heads.

With this Series the highest level of count accuracy is granted by different counting technologies solutions available (Optical sensor and E.F.S. – Electronical field sensor) which are able to work also in difficult conditions. Moreover, SWIFTPHARM 2 is extremely easy to clean and its integrated guards design allows a perfect integration of containment solution if needed.

- No additional space is required at the back of the counter for cleaning procedure.

- The simpler layout allows a simpler cleaning procedure and reduce the down time.

- Integrated guard design lending towards higher levels for product isolation.

IMA TB4S Electronic tablet counter

The TB4s is a stainless steel electronic tablet counter that offers an extremely versatile and accurate method of counting of most shapes of tablet, capsule, dragee hard and soft gelatine capsules.

IMA ILS-1 In line sorter – Linear unscrambler

ILS-1 is a new linear unscrambler with integrated bulk hopper, ionized air rinse and inspection for highly efficient bottle feeding.

IMA ROTARY UNSCRAMBLER Automatic bottle unscrambler

This Series has been designed to handle a wide range of plastic bottles and is available in 3 sizes dependent upon output. This fully guarded machine is constructed to meet the latest requirements for GMP.

Bottles are loaded randomly into the large covered hopper from where they are raised into the starwheel by the flighted infeed. The starwheel separates the bottles, loading them into pockets. Each container is then transported to a secondary starwheel for placement onto a conveyor, upside down bottles are ejected using compressed air. As an integrated system the rotary unscrambler can be synchronized to line outputs and container backup controls will start and stop the system on demand.

With few quick release change parts the system can be easily changed over to different bottle formats in 5 minutes without the use of tools.

- Large storage hopper.

- Stainless steel/acrylic construction.

- Safety guarding.

PPS Service & Aftersales

Uniquely for the industry PPS has its own service department, which is of great benefit to our customers. PPS service department has specially trained technicians with the highest expertise and experience. We offer a long list of services, including:

- Installation and renovation of existing equipment.

- Design of complete solutions; everything from the requirements specifications and logistics, to execution and validation.

- Competent feedback on automation solutions or other type of production optimization.

- Installing and/or moving entire production or packaging lines.

- Training of technical personnel and operators in optimal use of the installed equipment.

- Tailor-made service and aftersales agreements for ongoing maintenance as well as assistance in case of breakdown.

In addition, PPS delivers spare parts and consumables directly to our customers from own stock. Having our own stock ensures fast and efficient delivery, which minimizes any production downtime for our customers.

If you want to know more about our service department, please contact us directly or get more information here.