IMA Sterilization

Sterilization systems are a crucial component in the processing of a large number of pharmaceutical and medical products. Besides the sterilization equipment itself process validation is required, including documentation of cycle repeatability and the functions of the sterilization system.

PPS and IMA supply sterilization solutions to meet all of the above requirements as well as any additional ones you may have.

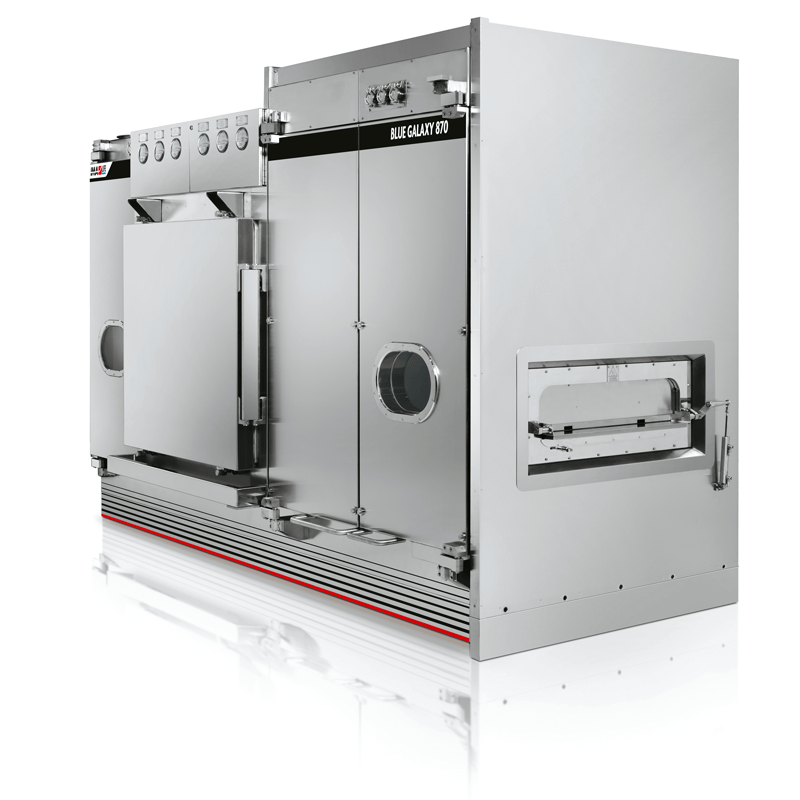

IMA BLUE GALAXY Depyrogenating Tunnels

All pharmacopoeia indicate Escherichia Coli type 5 as the endotoxin to be used for checking that a de-pyrogenation process is accomplished correctly. A de-pyrogenation process has to initially guarantee at least a log 3 reduction of endotoxins.

IMA BLUE GALAXY is a series of de-pyrogenating tunnels designed to be incorporated in production lines that require continuous de-pyrogenation by means of dry heat. The wide range available responds adequately to any production requirement; top-level design technology allows use in any kind of application; easily integrated intolines handling highly toxic compounds or equipped with isolators.

- Completely automatic unloading procedure.

- The system for air balancing, pressurisation and heating/cooling enables effective thermal treatment of glass containers.

- Control and automation system set-up with different PLC or PC types.

- Dry-heat/VHP sterilisation of cooling zone (IMA Life patent pending).

- Reduction of endotoxins >log 3.

PPS Service & Aftersales

Uniquely for the industry PPS has its own service department, which is of great benefit to our customers. PPS service department has specially trained technicians with the highest expertise and experience. We offer a long list of services, including:

- Installation and renovation of existing equipment.

- Design of complete solutions; everything from the requirements specifications and logistics, to execution and validation.

- Competent feedback on automation solutions or other type of production optimization.

- Installing and/or moving entire production or packaging lines.

- Training of technical personnel and operators in optimal use of the installed equipment.

- Tailor-made service and aftersales agreements for ongoing maintenance as well as assistance in case of breakdown.

In addition, PPS delivers spare parts and consumables directly to our customers from own stock. Having our own stock ensures fast and efficient delivery, which minimizes any production downtime for our customers.

If you want to know more about our service department, please contact us directly or get more information here.