IMA Powder Mixer

Together with IMA, PPS supplies a number of different powder mixer solutions for both wet and dry products, and for both laboratory use and full scale production. Additionally, we offer various drum and container blenders from Müller.

With a wide range of supplementary equipment, we can offer a flexible solution adapted to customer specific requirements, also after equipment installation.

PPS also offers fluid bed equipment for powder and solids production.

IMA ROTO MIX High Shear Mixer Granulator

The Powder mixer – ROTO MIX High Shear Mixer Granulator is the latest generation high shear granulator. Inspired by the consolidated Roto technology existing in the pharmaceutical industry since the 1980s, IMA ROTO MIX ensures the optimum shear for granulation at all speeds.

ROTO MIX is a high shear mixer granulator designed for the dry mixing of powders and wet granulation. Mixing and agglomeration of powder particles is achieved by the combined action of impeller, chopper and liquid binder distributor. Available in a through-the-wall version, ROTO MIX optimises the room layout and fits seamlessly into solid dose processing lines.

- Suitable to work in high containment: product transfers and surfaces in contact with the product are significantly reduced.

- Dust-free process, safe use of solvents and reduced risk of contamination.

- Unique impeller design to prevent product sticking and maximize product yield.

IMA ROTO CUBE – Single-pot processor

Developed in 1984, ROTO CUBE is the benchmark for single-pot granulation. Accurate detection of the wet granulation end-point, tilting bowl and gas stripping (GA.ST.) during vacuum drying all ensure highly efficient processes and premium quality granules.

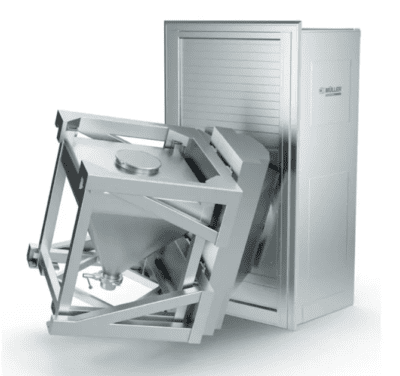

Müller Drum & Container Mixer

PPS supply various containers from Müller matched to specific production needs. Since the blending container is not permanently integrated into the plant, it can also serve as a transport container, e.g., with a pallet truck or a trolley. This saves time, costs, and resources.

- Load capacity up to 1,500 kg.

- Designed according to GMP.

- Individual configuration of the blending parameters in terms of rotational speed and direction.

PPS Service & Aftersales

Uniquely for the industry PPS has its own service department, which is of great benefit to our customers. PPS service department has specially trained technicians with the highest expertise and experience. We offer a long list of services, including:

- Installation and renovation of existing equipment.

- Design of complete solutions; everything from the requirements specifications and logistics, to execution and validation.

- Competent feedback on automation solutions or other type of production optimization.

- Installing and/or moving entire production or packaging lines.

- Training of technical personnel and operators in optimal use of the installed equipment.

- Tailor-made service and aftersales agreements for ongoing maintenance as well as assistance in case of breakdown.

In addition, PPS delivers spare parts and consumables directly to our customers from own stock. Having our own stock ensures fast and efficient delivery, which minimizes any production downtime for our customers.

If you want to know more about our service department, please contact us directly or get more information here.