Washing and cleaning

PPS offers different washing and cleaning solutions for processing. Together with IMA and Müller we offer washing and cleaning systems for format parts, drums and bins – as well as supply washing and sterilization systems for vials and ampoules. We also offer standard cleaning systems and tailor-made solutions, including customized racks.

All cleaning systems are designed to meet the highest cGMP and EHEDG regulations. The high-quality automated cleaning systems ensure reproducible cleaning, rinsing, and drying processes – and subsequently, the highest product safety.

IMA AQUARIA washer

AQUARIA is IMA Active’s all-in-one washer for components, tools, and machine parts. It maximizes the washing chamber volume while minimizing the size of the machine.

Powerful yet essential, effective, and smart.

Different configurations are available thanks to the plug-and-play shift among machine groups and layout options. This flexibility enables AQUARIA to meet any space requirement and optimize installation and maintenance operations.

Simplified washing concepts, based on intelligent design and GMP compliance for maximum efficiency, enable the washer to fully respond to industry requirements. Easily integrated with other equipment, AQUARIA fits seamlessly into solid-dose processing lines.

A variety of configurations help keep consumption under control, ensuring greater efficiency and respect for the environment.

Highlights of AQUARIA:

- Automatic dose regulation

- Compact design ensures a minimum footprint

- Rotation sensors for correct rotation during washing

- Cutting-edge HMI

IMA ATLANTIS Washing station

High efficiency with minimum consumption. Available in three models, ATLANTIS ensures optimal performance with maximum flexibility in terms of machine configurations and washing cycles.

IMA VENUS Parts washer

A combination of IMA Active’s technological expertise and knowledge of the pharmaceutical industry, VENUS achieves top-level performance while minimising water and detergent consumption thanks to its recirculation system.

VENUS is IMA Active’s all-in-one solution to wash components and parts of different sizes and volumes in a completely automatic mode. Available in two models (900 and 1200), VENUS works with a water recirculation system at low pressure and high flow rate.

IMA HYDROWASH Washing machine

High efficiency and compact design. Easily positioned inside the working area, HYDROWASH is designed in compliance with the highest GMP standards for installations with sanitary water.

IMA HYDRA Linear vial washer

HYDRA was created after many years of research and development focusing on container decontamination for injectable drugs. Designed according to the cGMP guidelines, the machine features the highest quality standards required by the pharmaceutical industry.

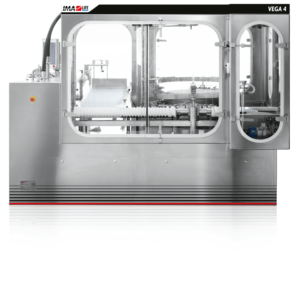

IMA VEGA Rotary Vial Washers

Containers coming in contact with parenteral preparations must be rendered sterile and non-pyrogenic, process resulting particularly successful with the VEGA Series, where the easy configurable washing sequence enhances the efficiency of the cleaning procedure

IMA HYDRA 100/300/400 Vial external washer

Conceived for outer surface decontamination of pharmaceutical containers after the filling process, Hydra 100/300/400 minimizes the legal risk of long-term exposure for packaging operators and medical personnel handling cytotoxic products or potent compounds.

The rotary external washers Hydra 100/300/400 have been designed to perform the decontamination of external surfaces of glass or plastic cylindrical containers (bottles, vials, etc.) potentially contaminated by the product during the filling process.

The decontamination process can be carried out using water or by adding to the water a dedicated washing media in case of toxic products, in order to avoid any risk of contamination.

Ideal for completion of aseptic processing lines, Hydra 100/300/400 are the perfect solution for any output.

IMA VEGA 400 Ampoule external washer

Müller GMP washer for drums and smaller parts

A Müller washing system is a flexible solution that can be adjusted to individual requirements. The GMP-compliant design of the washer enables flexible automated cleaning of practically all washable production goods in a GMP environment. And they guarantee that no cross-contamination and germ formation occurs.

The washer for smaller parts is an integrated cleaning device for inside and outside cleaning of smaller parts such as drums, bottles, trays, pumps, filling line equipment, parts from tablet presses, and laboratory glassware.

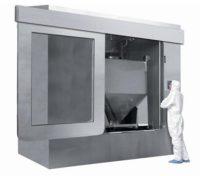

Müller GMP cleaning system for containers and large parts

Müller GMP washers allow flexible cleaning of all parts used in pharmaceutical production. The cleaning system can be used for interior and exterior cleaning of containers, IBC’s, drums, vessels, barrels, and boxes.

The innovative technology provides best-in-class efficiency and lower purified water consumption. The systems are in compliance with the latest GMP requirements, and the state-of-the-art hygienic design offers the highest level of product safety.

Cleaning solutions with tailor-made chamber sizes and individual system layouts for a variety of technical requirements are available.

PPS Service & Aftersales

Uniquely for the industry PPS has its own service department, which is of great benefit to our customers. PPS service department has specially trained technicians with the highest expertise and experience. We offer a long list of services, including:

- Installation and renovation of existing equipment.

- Design of complete solutions; everything from the requirements specifications and logistics, to execution and validation.

- Competent feedback on automation solutions or other type of production optimization.

- Installing and/or moving entire production or packaging lines.

- Training of technical personnel and operators in optimal use of the installed equipment.

- Tailor-made service and aftersales agreements for ongoing maintenance as well as assistance in case of breakdown.

In addition, PPS delivers spare parts and consumables directly to our customers from own stock. Having our own stock ensures fast and efficient delivery, which minimizes any production downtime for our customers.

If you want to know more about our service department, please contact us directly or get more information here.