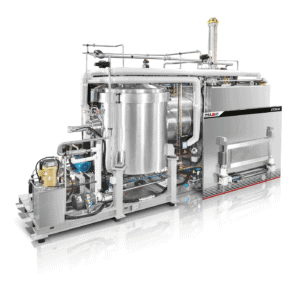

IMA Freeze dryer

Freeze drying – or lyophilization – is a process that removes water from a product at low temperatures. First, the substance is frozen. It is then dried by sublimation of ice under vacuum pressure. This is done without damaging or changing the product. It is a sensitive process that requires the highest level of protection. Freeze drying is a much gentler way of dehydrating a substance than other methods that require high temperatures. High temperatures risk destroying or changing the product.

A freeze-dried product can easily be rehydrated again by adding water. Freeze drying also significantly extends shelf life. This makes the method particularly applicable for a large number of products in the pharmaceutical and biotech industry.

Together with IMA, PPS supplies containment freeze drying equipment as well as freeze dryers for lab scale and production purposes. Additionally, we offer filling, loading and unloading equipment, also from IMA, offering the benefit of the entire freeze dryer solution coming from the same supplier.

IMA LYNFINITY Continuous Aseptic Spray-Freezy-Drying

Raising productivity and reducing downtime is now possible in a continuous aseptic process, with constant monitoring from fermentation to final packaging.

IMA LYOMAX Industrial Freeze Dryer

Freeze-drying involves removal of solvent such that the molecular structure of the active ingredient of the drug is least disturbed, thus providing a dried drug product that is stable over time.

IMA MINIMAX Small-scale Freezy Dryer

Based on the successful LYOMAX industrial FD concept, MINIMAX is a GMP, small-scale freeze dryer developed to address the demands involved in handling small production batches.

IMA LYOFAST Industrial Freeze Dryer

Freeze-drying of biopharmaceuticals has become a routine procedure, which leads to an increase in product stability. LYOFAST is the pre-engineered cost-effective, reliable and efficient standard solution.

The freeze drying process has important applications in the pharmaceutical and biotechnology industries, and pharmaceutical freeze drying is now a standard process used to stabilize, store or increase the shelf life of drug products and other biologicals.

LYOFAST is IMA Life solution to keep freeze-drying competitive as a pharmaceutical processing step.

For either bulk format or liquid in vials, ampoules or syringes, the LYOFAST units are designed for freeze drying high value products, such as: vaccines, antibiotics, cytostatics, biologicals, hormones, active ingredients, and reactives.

IMA LYOFAST MINI Pilot Freeze Dryer

The new compact LYOFAST MINI range of freeze dryers provides the link between laboratory development, pilot and industrialized production.

IMA MINIFAST Pilot Freeze Dryer

The MINIFAST range of freeze dryers is the connecting factor between a typical bench-top freeze dryer used in the laboratories and the GMP production scale ones.

PPS Service & Aftersales

Uniquely for the industry PPS has its own service department, which is of great benefit to our customers. PPS service department has specially trained technicians with the highest expertise and experience. We offer a long list of services, including:

- Installation and renovation of existing equipment.

- Design of complete solutions; everything from the requirements specifications and logistics, to execution and validation.

- Competent feedback on automation solutions or other type of production optimization.

- Installing and/or moving entire production or packaging lines.

- Training of technical personnel and operators in optimal use of the installed equipment.

- Tailor-made service and aftersales agreements for ongoing maintenance as well as assistance in case of breakdown.

In addition, PPS delivers spare parts and consumables directly to our customers from own stock. Having our own stock ensures fast and efficient delivery, which minimizes any production downtime for our customers.

If you want to know more about our service department, please contact us directly or get more information here.