Product handling

PPS supplies a wide range of product handling systems from IMA and Müller, covering equipment for storing, lifting and transporting.

We offer high-quality product handling solutions for most types of products, including liquids, solids and toxics. Moreover, we supply product handling systems for cleanroom environment.

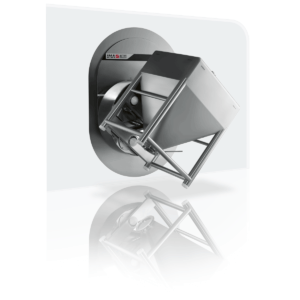

IMA CYCLOPS Bin tumbler

Versatility and high performance are the hallmarks of IMA Active’s bin tumblers. CYCLOPS ensures efficient mixing thanks to its 15° rotation axis while minimizing the need for tumbler decontamination.

IMA CYCLOPS is a bin tumbler designed for blending and homogenizing powders and granules for the pharmaceutical, food and chemical industries. The machine can be installed through-the-wall for top-level GMP configuration and space saving in the processing area.

- High productivity ensured by hermetically closed IBCs: different products can be blended without the need for decontamination.

- “Trigon System” to completely block and blend a large series of bins without additional devices.

- Dual blending inclination, with the rotation axis inclined also on the vertical plane, for difficult-to-blend products.

IMA TWINVALVE High containment valve

No system can obtain the maximum Occupational Exposure Level without washing its valves. TWINVALVE combines IMA Active’s experience in powder handling and washing systems to ensure high containment.

IMA TWINVALVE is a reliable solution to handle powders, granules, tablets and capsules in high containment.

This patented system can be used as a standard butterfly valve on bins and can be easily retrofitted on existing powder handling plants allowing containment during powder transfer.

- Simple design composed of two standard sanitary butterfly valves with an orbital rotating spray head.

- Different cleaning cycles allowed: cleaning by compressed air and cleaning by water/solvent.

- Drying phase by compressed air or steam performed at the end of the cleaning cycle.

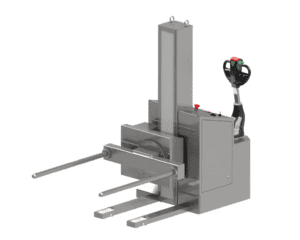

IMA HERCULES Column lifter

HERCULES is IMA’s latest generation of lifting columns. Available in three different models, HERCULES is equipped with the certified Blocstop™ system to ensure optimal safety with maximum resistance.

HERCULES lifting columns are designed for handling drums, containers, Intermediate Bulk Containers (IBCs/Bins) and small machines like pneumatic conveyors, mills and calibrators.

The three models cover different ranges of useful capacity and are also available in the Mix version, combining lifting and blending.

- Main motor positioned at the basement for easy maintenance.

- Certified Blocstop™ to stop the lifting arm in case of failure.

- Load cell weighing system to stop overload as an option.

IMA TWISTER Transfer system

Flexibility is the hallmark of IMA Active’s handling systems. Easily integrated with other equipment into solid dose processing lines, TWISTER allows product transfer in high containment.

TWISTER is a gravity transfer system designed to transfer powders, granules, tablets and capsules from a bin docking station to a processing or packaging machine in dust-tight conditions. IMA TWISTER ensures slow product descent minimizing powder/granule de-mixing or tablet/capsule damaging as much as possible.

- Slow product descent to avoid product de-mixing or damage.

- Safety ensured by the double tube solutions.

- Easy maintenance and cleaning thanks to accurate design and smooth finishing.

IMA BDS Bag dumping station

Simple design, reduced dimensions, accurate finishing. These key features make BDS a versatile accessory for the optimisation of powder and granules handling in the pharmaceutical industry.

The IMA BDS Bag Dumping Station for powders or granules is designed for discharging bags and small containers in contained conditions, reducing the contamination level of the working environment. Thanks to its front port and bottom outlet in dust-tight conditions, BDS can be easily integrated with the loading and unloading devices of the Pharma Handling Systems.

- Internal parts manufactured in AISI 316 stainless steel, mirror polished.

- Easy cleaning thanks to smooth finishing without dead corners.

- Large front opening to enable perfect accessibility during loading operations.

IMA CANGURO Bin tumbler

Smart design, prime performance, enduring reliability. CANGURO’s compact GMP design makes blending smooth and highly efficient, achieving outstanding results with little maintenance.

CANGURO is a very compact bin tumbler designed for blending and homogenizing powders and granules.

The machine is equipped with an over-rotation feature for product leveling inside the IBC. The rotation speed can be adjusted according to specific requirements.

- High productivity ensured by hermetically closed IBCs: different products can be blended without the need for decontamination.

- Single arm frame for easy bin positioning and blocking.

- Double 15° inclination angles for high-efficiency blending and over-rotation feature for product leveling inside the bin.

IMA PH-BIN and PH-DRUM

Designed according to the most restrictive GMP requirements, PH-BIN and PH-DRUM ensure perfect efficiency with no product losses. Their large bending radius without dead corners avoids product residue and facilitates cleaning operations.

PH-BIN is designed for handling and blending powders and granules. Fitted with “Trigon” or “Aries” holding systems, it can be interfaced with the loading and unloading devices of the Pharma Handling Systems.

Also built in AISI 316 stainless steel, PH-DRUM is fitted with an upper lid complete with clamp connection to avoid product dispersion.

- Perfect efficiency ensured by rectangular cross section and inclination of the upper part of PH-BIN.

- Spider version available: its reduced volume compared to standard bins ensures great flexibility and the processing of small batches.

- T-Bin available to handle capsules and tablets: its decentralized loading lid simplifies product loading operations.

IMA SWIFTLIFT Tablet elevator

The IMA Swiftpack SWIFTLIFT Tablet Elevator has been designed to transport product from a floor mounted hopper to a tablet counter, blister packing machine or similar.

The machine is constructed in stainless steel with specification in accordance with the latest requirements for GMP. It can be completely dismantled for cleaning without the use of tools.

- 100 liter product hopper. Larger sizes are available.

- Vibratory feed system with chip sieve and dust extraction points.

- Single elevator bucket with auto level detection.

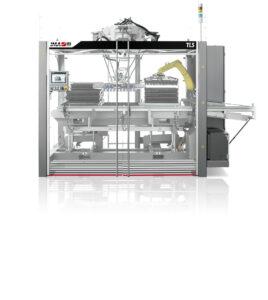

IMA TLS Top Loading System

TLS is a robotic system able to load/unload products from/to trays. This machine has been devised to enhance production line performance with great flexibility of functions, product handling and layout.

The IMA robotic manipulation system can handle the most unstable and irregularly shaped products, with the utmost accuracy taking care of them without damages.

- PLC unit interacts with robot processor for straightforward operation.

- Operator interface for fast changeover procedures and assistance with diagnostics.

- Transparent guards interlocked with safety switches.

Müller Storing Equipment

Drums

We offer a large selection of high-quality steel drums of different shapes, volume, and material. We supply ultraclean drums with sterile closures, drums for storing and handling toxic substances, and for extreme conditions such as high pressures and temperatures.

IBC & Containers

Containers come in many shapes and sizes, such as cylindrical, rectangular, or IBCs. We supply containers for large volumes of up to 2,000 litres and offer solutions for a wide range of applications. All containers are of highest quality with ISO 9001: 2000 certification and designed in compliance with ATEX.

Müller Lifting Systems

Mobile lifters

We supply a number of mobile lifters for picking up drums, transporting, tilting and emptying. We offer the highest flexibility with mobile lifters for maneuvering in very restricted spaces or rooms with low headspace.

Pallet lifting and handling systems

We offer a range of pallet handling systems for lifting, turning, and moving pallets of up to 2,300 kg. All pallet handling systems are designed completely in stainless steel, and some are specially designed to be used in cleanroom environments.

Drum lifting and handling systems

Equipment for handling drums is available in many different versions; all designed for ergonomic and flexible use and build entirely in stainless steel. We offer drum lifters with loading capacity of up to 350 kg.

Müller Handling Systems

Dust-free handling

For dust-free processing PPS supplies complete dust-free systems from Müller. With all the different components for dust-free processing, we can offer individualised solutions to meet your needs and requirements, and still provide a simple and cost-effective solution. Dust-free handling components available include butterfly valves.

Big bag handling

For big bag handling, PPS offers a selection of equipment for unloading and transporting, standard as wells as customized solutions. Unloading stations handle up to two tons and loads by forklift or with integrated crane and hoist. Dust-free operation is available.

Vacuum transport

Vacuum conveyors offer safe and hygienic product handling. The vacuum conveyors are designed to meet the highest quality standards, for frequent product changes, quick and easy cleaning, and for dismantling without using tools. WIP (Washing-In-Place) and CIP (Cleaning-In-Place) systems are available as an option.

PPS Service & Aftersales

Uniquely for the industry PPS has its own service department, which is of great benefit to our customers. PPS service department has specially trained technicians with the highest expertise and experience. We offer a long list of services, including:

- Installation and renovation of existing equipment.

- Design of complete solutions; everything from the requirements specifications and logistics, to execution and validation.

- Competent feedback on automation solutions or other type of production optimization.

- Installing and/or moving entire production or packaging lines.

- Training of technical personnel and operators in optimal use of the installed equipment.

- Tailor-made service and aftersales agreements for ongoing maintenance as well as assistance in case of breakdown.

In addition, PPS delivers spare parts and consumables directly to our customers from own stock. Having our own stock ensures fast and efficient delivery, which minimizes any production downtime for our customers.

If you want to know more about our service department, please contact us directly or get more information here.