Tamper-evident labeling

Tamper-evident labeling to prevent counterfeit

Tamper-evident labeling is used on prescription drugs among others, to prevent counterfeits. Counterfeit drugs harbor considerable health risks and it is a huge problem worldwide. Consumers seldom realize that they can easily put their health at risk when buying prescription drugs that may have been tampered with.

Given the huge profits, drug counterfeiters often dilute or omit the active ingredients, or replace them with ineffective or even, in the worst case, dangerous substances. It is not only the internet trade that poses a danger to the consumers – falsified and tampered medicines can also enter the regular circulation in some circumstances. At present, counterfeit medicines can be almost impossible to detect with the untrained eye.

To prevent tampering, all pharmaceutical packaging of prescription medicine in the EU, since February 2019, must now include a tamper-evident closure and serilization as a security feature. This is stipulated by the EU Directive 2011/62/EU adopted in 2011. In order for pharmacists, health personnel and consumers to recognize when the product was opened without authorization, the packaging must be visibly and irreversibly damaged when first opened.

To continue to use the existing folding boxes, the use of sealing labels is of particular interest in terms of cost-effectiveness. These labels firmly connect the insertable tags to the body of the package. The most practical labels from an economic and technical point of view are completely conventional rectangular or round labels. These labels may include a security perforation.

The essential factor for their use is the pressure-sensitive adhesive. It must be highly resistant to water, hot air and various solvents. This is the only way to guarantee that the label cannot be peeled off even heavily coated folding boxes, without visibly destroying either the label or the box. The same type of sealing label can therefore be used for a variety of packaging materials and for a variety of surfaces – even hot melt-sealed boxes can be protected against tampering using this method. (source ref.: Herma)

Tailored and standard solutions

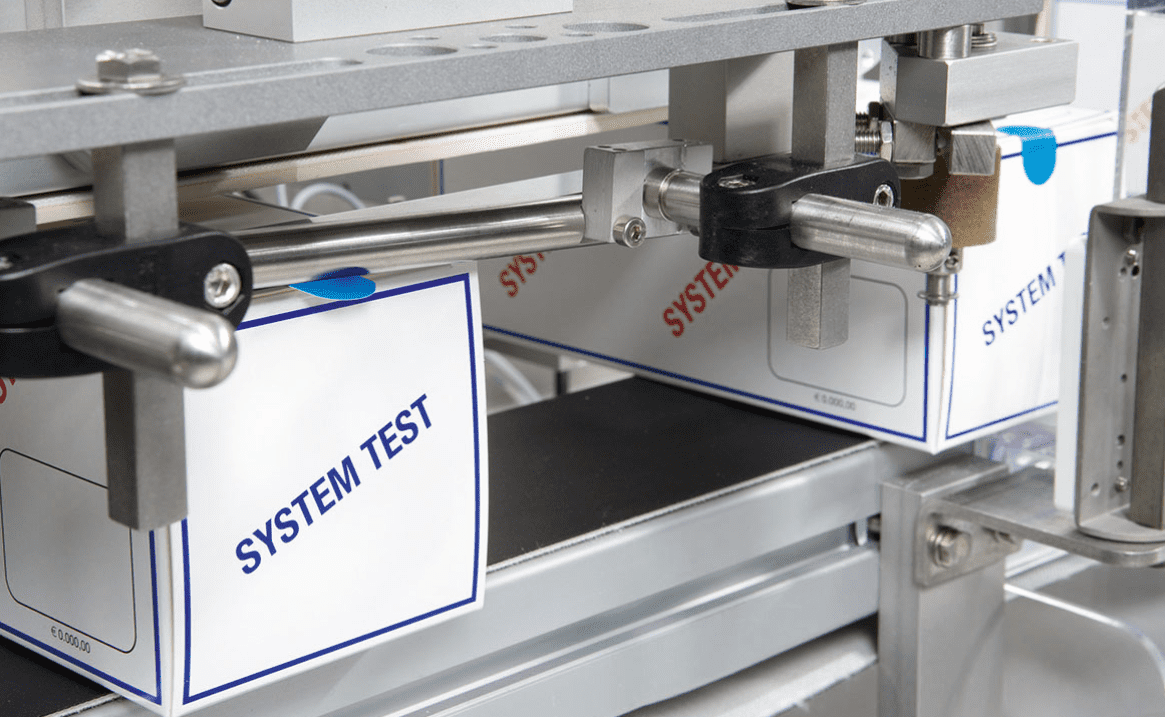

Tamper-evident labeling is most often used in the pharmaceutical and food industries, but we offer solutions from Herma for all industries. Herma is a leading specialist in self-adhesive technology and their labeling systems for tamper-evident labeling is based on the technology of proven standard modules but can be specially designed according to individual requirements.

The use of tamper-evident labels requires a high degree of precision. The tamper-evident labeling equipment can also be equipped with printers and cameras in order to print, verify, and collect data for serialization of pharmaceutical products. The labeling machines can easily be integrated into the existing production environment.

With tamper-evident labeling equipment from Herma you get:

- Labeling speed up to 300 units per minute.

- In combination with printer and camera, it works as a complete serialization unit for pharma production.

- Different solutions are offered according to your needs.

Wish to know more?

Contact us today if you have any questions or wish to hear more about your options within tamper-evident labeling.

PPS Service & Aftersales

Uniquely for the industry PPS has its own service department, which is of great benefit to our customers. PPS service department has specially trained technicians with the highest expertise and experience. We offer a long list of services, including:

- Installation and renovation of existing equipment.

- Design of complete solutions; everything from the requirements specifications and logistics, to execution and validation.

- Competent feedback on automation solutions or other type of production optimization.

- Installing and/or moving entire production or packaging lines.

- Training of technical personnel and operators in optimal use of the installed equipment.

- Tailor-made service and aftersales agreements for ongoing maintenance as well as assistance in case of breakdown.

In addition, PPS delivers spare parts and consumables directly to our customers from own stock. Having our own stock ensures fast and efficient delivery, which minimizes any production downtime for our customers.

If you want to know more about our service department, please contact us directly or get more information here.