IMA Powder filling

Within powder filling, IMA delivers high-quality powder dosing systems for filling into vials or bottles, also for sterile powders.

For both types of powder fillers, we offer standard and customized solutions, which can be integrated with secondary packaging lines.

PPS also supplies different solutions for further tablet production. In here both tablet coating, primary packaging with pharmaceutical blister packaging machines and later secondary packaging. PPS are also at your service when it comes to sterilization solutions.

IMA LYNFINITY Continuos Aseptic Spray-Freeze-Drying

Raising productivity and reducing downtime is now possible in a continuous aseptic process, with constant monitoring from fermentation to final packaging.

LYNFINITY spray-freeze-drying process features a controlled spray of liquid product into a cryogenically cooled freezing chamber. The resultant frozen particles of the liquid product are freeze-dried in the drying module. The drying chamber contents are both transported and heated to promote rapid sublimation and prevent agglomeration.

The continuous spray-freeze-drying process starts with bulk liquid product and ends with the discharge of dried particles, featuring total containment from formulation to powder filling. This enables higher sterility assurance levels, whereas traditional freeze-drying requires additional external material handling, for example during filling. Upon completion of drying, the uniform, dried spherical product allows for the use of a variety of containers (vials, syringes, inhalation systems etc.).

- Designed for continuous process from fermentation to final packaging

- Greater throughput flexibility: minimization of scale up and scale down challenges

- Better quality attributes: improved product uniformity through a gentle drying process

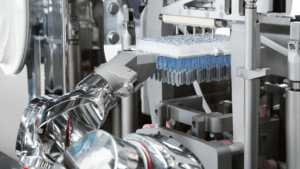

IMA INJECTA

The use of advanced robotic-driven manipulations versus conventional handling systems improves product quality and manufacturing efficiency.

INJECTA handles pre-sterilised Ready-To-Use containers (syringes, vials or pre-capped cartridges), pre-oriented vials in trays as well as sterilised vials from the depyrogenation tunnel. This allows for high process flexibility and adaptability.

Specialised robots perform all handling activities with no glass-to-glass contact and without operator intervention. The result is less time spent validating aseptic conditions and superior agility for multi-product manufacturing.

- Precise, accurate and reliable fill-finish process

- Single rejection of individual non-conformities both from the nest or with de-nesting

- Perfectly suited to isolation technology or different containment solutions

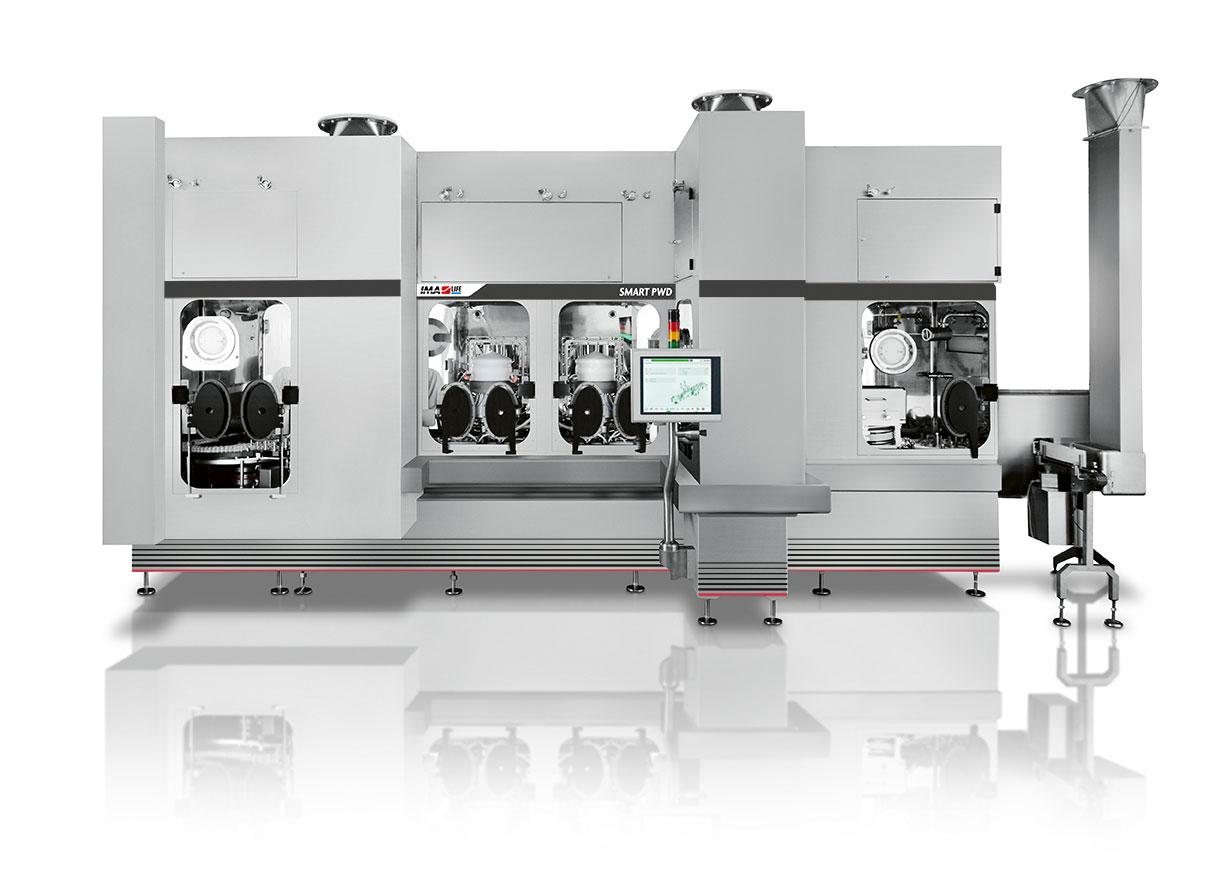

IMA SMART PWD Powder filling & stoppering machine

Today, certain bacteria have developed resistance to antibiotics that were once commonly used to treat them. The implementation of more powerful antibiotics, and new aseptic technologie, like SMART PWD contribute to solving this serious public health issue.

Antibiotic-resistant bacteria are bacteria that are not controlled or killed by antibiotics. They are able to survive and even multiply in the presence of an antibiotic. In order to address this public health concern, the research, development and handing of a “new generation” of antibiotic powders are key themes within the Pharmaceutical Industry.

IMA Life’s SMART PWD is the straightforward solution to comply with this crucial issue, able not only to process difficult powders accurately, but also to simultaneously dose, by vacuum-pressure as well as by auger technology, two different types of pharmaceutical products inside the same vial with single 100% check-weighing.

- Vacuum-pressure powder filling system or auger technology.

- Possibility of dosing up to 2 different pharmaceutical powders into the same vial.

- Advanced 100% IPC with speeds of up to 120 pcs/min.

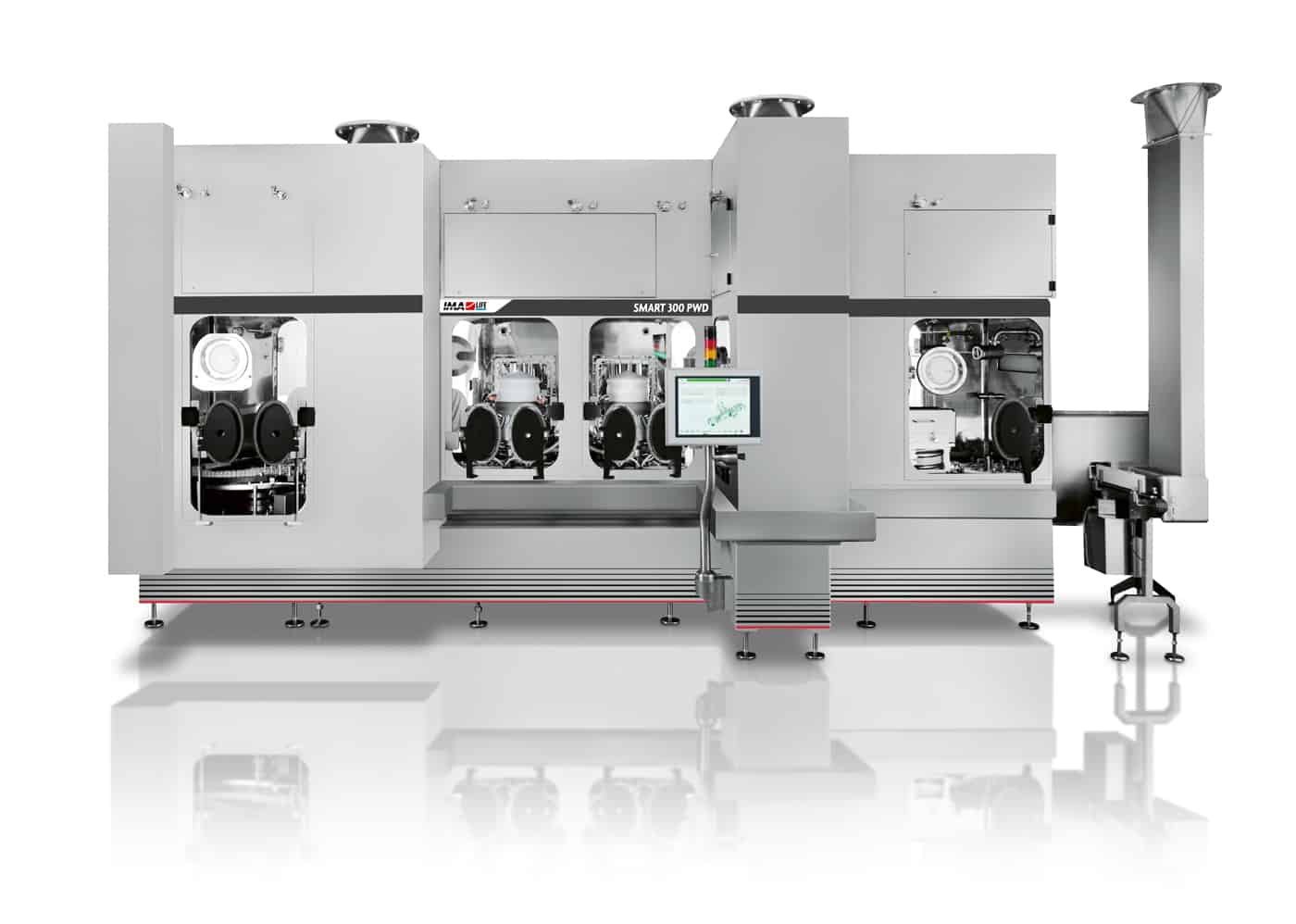

IMA SMART 300 PWD AUGER High-Speed Powder Dosing & Stoppering Machine

The rising demand for operator safety in aseptic processing, when handling high-potent powdered substances, has boosted the research and the adoption of innovative aseptic dosing technologies replacing the traditional methods.

IMA has adressed issues such as safety, cleanliness and high containment requirements with the IMA SMART 300 PWD AUGER and its innovative powder-processing concept and technology. The auger techonology ensures close to zero product loss.

IMA MACRO PWD Powder macrodosing machine

Macro PWD is the result of over 50 years of experience in pharmaceutical powder filling and over 100 machines installed worldwide. Able to satisfy the current safety requirements, it is the answer to the increasing demand for the dosage of dry syrups.

Macro PWD is an automatic intermittent motion machine designed to dose powder, granules and milled products in glass or plastic bottles and jars.

The powder dosing system features the consolidated auger technology, which guarantees extreme precision and product safety even in the case of long production cycles.

Depending on customers’ requirements, the machine is available in three different configurations and ensures easy access to the working area and excellent visibility during production.

- Accurate and clean filling.

- Positive transport system.

- Minimum and maximum bottle inlet/outlet loading sensors.

PPS Service & Aftersales

Uniquely for the industry PPS has its own service department, which is of great benefit to our customers. PPS service department has specially trained technicians with the highest expertise and experience. We offer a long list of services, including:

- Installation and renovation of existing equipment.

- Design of complete solutions; everything from the requirements specifications and logistics, to execution and validation.

- Competent feedback on automation solutions or other type of production optimization.

- Installing and/or moving entire production or packaging lines.

- Training of technical personnel and operators in optimal use of the installed equipment.

- Tailor-made service and aftersales agreements for ongoing maintenance as well as assistance in case of breakdown.

In addition, PPS delivers spare parts and consumables directly to our customers from own stock. Having our own stock ensures fast and efficient delivery, which minimizes any production downtime for our customers.

If you want to know more about our service department, please contact us directly or get more information here.

IMA Powder filling

Within powder filling, IMA delivers high-quality powder dosing systems for filling into vials or bottles, also for sterile powders.

For both types of powder fillers we offer standard and customized solutions, which can be integrated with secondary packaging lines.

PPS also supplies different solutions for further tablet production. In here both tablet coating, primary packaging with pharmaceutical blister packaging machines and later secondary packaging. PPS are also at your service when it comes to sterilization solutions.

IMA LYNFINITY Continuos Aseptic Spray-Freeze-Drying

Raising productivity and reducing downtime is now possible in a continuous aseptic process, with constant monitoring from fermentation to final packaging.

IMA SMART PWD Powder filling & stoppering machine

Today certain bacteria have developed resistance to antibiotics that were once commonly used to treat them. The implementation of more powerful antibiotics, and new aseptic technologie, like SMART PWD contribute to solving this serious public health issue.

IMA MACRO PWD Powder macrodosing machine

Macro PWD is the result of over 50 years of experience in pharmaceutical powder filling and over 100 machines installed worldwide. Able to satisfy the current safety requirements, it is the answer to the increasing demand for the dosage of dry syrups.

PPS Service & Aftersales

Uniquely for the industry PPS has its own service department, which is of great benefit to our customers. PPS service department has specially trained technicians with the highest expertise and experience. We offer a long list of services, including:

- Installation and renovation of existing equipment.

- Design of complete solutions; everything from the requirements specifications and logistics, to execution and validation.

- Competent feedback on automation solutions or other type of production optimization.

- Installing and/or moving entire production or packaging lines.

- Training of technical personnel and operators in optimal use of the installed equipment.

- Tailor-made service and aftersales agreements for ongoing maintenance as well as assistance in case of breakdown.

In addition, PPS delivers spare parts and consumables directly to our customers from own stock. Having our own stock ensures fast and efficient delivery, which minimizes any production downtime for our customers.

If you want to know more about our service department, please contact us directly or get more information here.