IMA pouch and sachet packing

Within pouch and sachet packing PPS offers a range of form-fill-seal solutions for both horizontal and vertical filling.

Together with IMA , we supply filling and packing equipment for a number of different industries, using various types of packing media, such as sachets, pouches, doy packs or bigger bags.

IMA BETA Vertical intermittent motion sachet machine

BETA Series ensures high performances thanks to the advanced technology developed. Benefit from the maximum flexibility in terms of configurations and production outputs to find the best solution for your goals.

IMA BETA Series vertical sachet packaging machines for 4-seal sachets can handle all types of product from paste products to fluid products, powders, free and non free flowing products, objects and accessories such as wipes. Multiple dosing systems can be installed for alternative productions and, in case of powder packaging, it is also possible to have a double auger to dose different powders into the same sachet.

High quality and aesthetically first-class sachets are produced as the seals are made during the stationary phase. BETA machines guarantee extremely easy size changeovers in terms of both sachet width and length.

- Maximum flexibility in terms of configurations

- High efficiency guaranteed

- Extremely easy and quick size changeovers in terms of both sachet width and length

IMA KAPPA Horizontal intermittent motion sachet machine

KAPPA Series is simply the highest expression of flexibility. These machines have been conceived to be fully customized according to customer requirements: huge range of sachet configurations handled, products and accessories fed, sachet sizes covered.

The machine is divided into two modules:

• A linear module which includes the following production functions: sachet vertical sealing, coding, corners rounding, film pulling and single sachet cutting.

• A rotating module which includes 8 stations to dose one or more products and subsequent

sachet sealing. With this configuration, dosing is performed away from the sealing areas where the temperature is high, so there is no risk of product heating.

This structure allows extreme compactness even if different dosing systems are installed.

- High flexibility in terms of sachet configuration, including special applications

- Different kinds of dosing systems available

- Wide range of sachet sizes covered

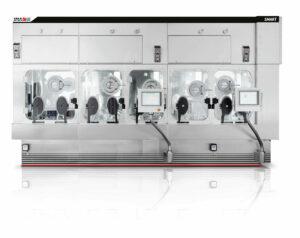

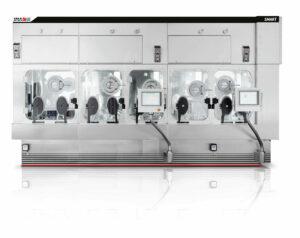

IMA SMART Filling, stoppering and capping machine

Time and ease of use are of the essence with small to medium batch production, but, with the SMART, IMA expertise realized something more: it combined proven simple technology with high standards of quality and reliability suitable to any aseptic filling need.

SMART is the answer to the increasing demand for even more flexible and versatile processing and packaging solutions. Short start-up times, easy changeovers and a high degree of automation are key considerations.

IMA SMART can be equipped with all types of dosing systems typical of the aseptic operations, and it is suitable for installation in cleanroom or under isolator, being all materials compatible with sterilizing agents and suitable for VHP exposure.

Available machine versions: SVP and LVP, with or without integrated capping module.

- Suitable for small batch production with output up to 120/vpm in the double-index configuration

- Slim & smart pharm design, fit for each type of lay out, even when space constraint is an issue

- Integrated capping operations in grade A environment

PPS Service & Aftersales

Uniquely for the industry PPS has its own service department, which is of great benefit to our customers. PPS service department has specially trained technicians with the highest expertise and experience. We offer a long list of services, including:

- Installation and renovation of existing equipment.

- Design of complete solutions; everything from the requirements specifications and logistics, to execution and validation.

- Competent feedback on automation solutions or other type of production optimization.

- Installing and/or moving entire production or packaging lines.

- Training of technical personnel and operators in optimal use of the installed equipment.

- Tailor-made service and aftersales agreements for ongoing maintenance as well as assistance in case of breakdown.

In addition, PPS delivers spare parts and consumables directly to our customers from own stock. Having our own stock ensures fast and efficient delivery, which minimizes any production downtime for our customers.

If you want to know more about our service department, please contact us directly or get more information here.

IMA Pouch and sachet packing

Within pouch and sachet packing PPS offers a range of form-fill-seal solutions for both horizontal and vertical filling.

Together with IMA , we supply filling and packing equipment for a number of different industries, using various types of packing media, such as sachets, pouches, doy packs or bigger bags.

IMA BETA Vertical intermittent motion sachet machine

BETA Series ensures high performances thanks to the advanced technology developed. Benefit from the maximum flexibility in terms of configurations and production outputs to find the best solution for your goals.

IMA BETA Series vertical sachet packaging machines for 4-seal sachets can handle all types of product from paste products to fluid products, powders, free and non free flowing products, objects and accessories such as wipes. Multiple dosing systems can be installed for alternative productions and, in case of powder packaging, it is also possible to have a double auger to dose different powders into the same sachet.

High quality and aesthetically first-class sachets are produced as the seals are made during the stationary phase. BETA machines guarantee extremely easy size changeovers in terms of both sachet width and length.

- Maximum flexibility in terms of configurations

- High efficiency guaranteed

- Extremely easy and quick size changeovers in terms of both sachet width and length

IMA KAPPA Horizontal intermittent motion sachet machine

KAPPA Series is simply the highest expression of flexibility. These machines have been conceived to be fully customised according to customer requirements: huge range of sachet configurations handled, products and accessories fed, sachet sizes covered.

IMA SMART Filling, stoppering and capping machine

Time and ease of use are of the essence with small to medium batch production, but, with the SMART, IMA expertise realized something more: it combined proven simple technology with high standards of quality and reliability suitable to any aseptic filling need.

SMART is the answer to the increasing demand for even more flexible and versatile processing and packaging solutions. Short start-up times, easy changeovers and a high degree of automation are key considerations.

IMA SMART can be equipped with all types of dosing systems typical of the aseptic operations, and it is suitable for installation in cleanroom or under isolator, being all materials compatible with sterilizing agents and suitable for VHP exposure.

Available machine versions: SVP and LVP, with or without integrated capping module.

- Suitable for small batch production with output up to 120/vpm in the double-index configuration

- Slim & smart pharm design, fit for each type of lay out, even when space constraint is an issue

- Integrated capping operations in grade A environment

PPS Service & Aftersales

Uniquely for the industry PPS has its own service department, which is of great benefit to our customers. PPS service department has specially trained technicians with the highest expertise and experience. We offer a long list of services, including:

- Installation and renovation of existing equipment.

- Design of complete solutions; everything from the requirements specifications and logistics, to execution and validation.

- Competent feedback on automation solutions or other type of production optimization.

- Installing and/or moving entire production or packaging lines.

- Training of technical personnel and operators in optimal use of the installed equipment.

- Tailor-made service and aftersales agreements for ongoing maintenance as well as assistance in case of breakdown.

In addition, PPS delivers spare parts and consumables directly to our customers from own stock. Having our own stock ensures fast and efficient delivery, which minimizes any production downtime for our customers.

If you want to know more about our service department, please contact us directly or get more information here.