IMA liquid filling machines for non-sterile and aseptic fluids

Together with our partner IMA, PPS supplies several different solutions for liquid filling, including sterile liquids. The technology behind is suitable for cosmetic products, pharmaceuticals, nutraceuticals, and other food supplements. We offer the best suitable solution for filling liquids into ampoules, bottles, vials, syringes, capsules, or tubes. The liquid filling equipment can be integrated into different packaging lines or other integrated solutions. Thereby you will benefit from the synergetic effects of integrating the entire packaging line.

Moreover, PPS supplies various high-performance solutions for washing or sterilizing bottles, vials, ampoules, and other glass or plastic containers. Washing solutions include both linear and rotary washers, as well as customized solutions. Sterilization systems include moist heat sterilization, dry heat sterilization, and ethylene oxide sterilization (EtO). Besides the sterilization equipment itself process validation is required, including documentation of cycle repeatability and the functions of the sterilization system.

Do not hesitate to contact us to discuss the solution ideal for your production.

Liquid filling machines

PPS offers a range of solutions for filling various liquids into glass or plastic containers, making them ideal for pharmaceutical, cosmetic, or food applications. The liquid filling machines can handle liquids of almost any viscosity and numerous container sizes and designs.

The high degree of automation optimizes the overall equipment effectiveness (OEE) of the liquid filling systems. The modular design and numerous configuration options present a solution that can be fitted to all customer specifications. Also, the filling machines can easily be combined with secondary packaging solutions.

- High quality liquid filling machines suitable for pharmaceuticals, nutraceuticals, other food applications, and cosmetic products.

- Compatible with a wide selection of closure types, such as spray pumps, droppers, pipettes, dosing cups, and different types of caps.

- All equipment is modular built and can be individually configured and precisely adapted to your specific requirements.

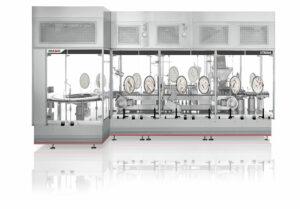

IMA EASYFILL Filling and stoppering machine

Designed to meet the requirements of the pharmaceutical industry in aseptic processing, EASYFILL is the right answer when a high degree of flexibility and modularity is required in sterile liquid filling.

Easyfill is a liquid filling and stoppering machine for vials, both small and large-volume parenterals, available in two models to satisfy medium and high-speed requirements.

The machine features a positive intermittent-motion, linear transport and brushless motors for precise movements. It can be equipped with all types of dosing systems typically used for aseptic products and with a checkweighing system composed of load cells for tare weight detection before filling and load cells for gross weight detection after dosing.

- No vial – no fill – no stoppering control device.

- Insertion of rubber stoppers for both liquid solutions and freeze-dried products.

- Suitable for integration with 100% In-Process Control.

Aseptic liquid filling machines

In addition to our filling equipment for non-sterile liquids, we also supply aseptic filling machines. All aseptic liquid filling machines from IMA guarantee excellent sterility assurance levels (SAL) and conforms to current Good Manufacturing Practice.

The aseptic filling systems offer efficient and reliable operation with high barrier protection. We offer first-class containment solutions to also protect the operator from any direct contact with toxic substances.

The aseptic filling machines can be configured as integrated solutions according to customer requirements, with selected upstream and downstream systems.

- Ideal for filling injection vials and infusion bottles for human and veterinary medical applications.

- Closing station can be either integrated into the liquid filler machine or work as a line component. Compatible with different closure types.

- RABS (Restricted Access Barrier System), vertical laminated flow systems, and integrated CIP (Cleaning in Place) and SIP (Sterilization in Place) systems available.

IMA INJECTA

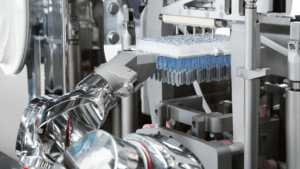

IMA INJECTA raises the bar for high-speed production of Ready-To-Use syringes and pre-capped cartridges.

The use of advanced robotic-driven manipulations versus conventional handling systems improves product quality and manufacturing efficiency.

INJECTA handles pre-sterilised Ready-To-Use containers (syringes, vials or pre-capped cartridges), pre-oriented vials in trays as well as sterilised vials from the depyrogenation tunnel. This allows for high process flexibility and adaptability.

Specialised robots perform all handling activities with no glass-to-glass contact and without operator intervention. The result is less time spent validating aseptic conditions and superior agility for multi-product manufacturing.

- Precise, accurate and reliable fill-finish process

- Single rejection of individual non-conformities both from the nest or with de-nesting

- Perfectly suited to isolation technology or different containment solutions

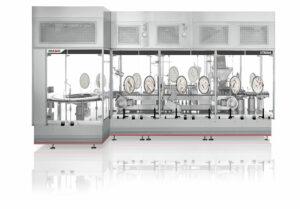

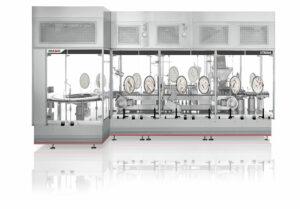

IMA XTREMA High speed filling & stoppering machine

The main concern of the pharmaceutical packaging market has always been the integrity of the drug, and, in the case of parenteral dosage forms, its sterility. XTREMA indeed embodies the latest technological breakthrough in aseptic filling.

XTREMA is your filler solution for product loss minimisation at high speed – up to 600 vials per minute.

It is an inline filling & stoppering machine with a positive inline transport system. The machine is suitable for filling liquid solutions into cylindrical vials and for the insertion of rubber stoppers. During the aseptic filling of dose containers, it is essential to prevent contamination, thus minimizing its exposure to environment, equipment, manipulation from operators, etc., until its sealing.

XTREMA fundamental characteristics respond to the industry’s stringent technical requirements of vial filling, and with its flexible and ergonomic design it assures the most complete possibility to integrate modular equipment.

- High speed filling with output up to 600 vpm

- Machine completely sealed and no tools required for size change over

- Ideal to be exposed to VHP (Hydrogen Peroxide in Vapour Phase)

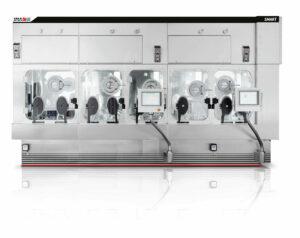

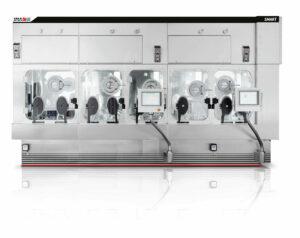

IMA SMART Filling, stoppering and capping machine

Time and ease of use are of the essence with small to medium batch production, but, with the SMART, IMA expertise realized something more: it combined proven simple technology with high standards of quality and reliability suitable to any aseptic filling need.

SMART is the answer to the increasing demand for even more flexible and versatile processing and packaging solutions. Short start-up times, easy changeovers and a high degree of automation are key considerations.

SMART can be equipped with all types of dosing systems typical of the aseptic operations, and it is suitable for installation in cleanroom or under isolator, being all materials compatible with sterilizing agents and suitable for VHP exposure.

Available machine versions: SVP and LVP, with or without integrated capping module.

- Suitable for small batch production with output up to 120/vpm in the double-index configuration

- Slim & smart pharm design, fit for each type of lay out, even when space constraint is an issue

- 100% check weighing of all filled vials

IMA LOADING SYSTEMS WITH TRAYS AND FENCES Semi-automatic vial loading & unloading systems

The aseptic production of pharmaceuticals usually takes place in cleanrooms in order to prevent contamination. IMA Life semi-automatic systems provide a controlled solution for loading fences in/out of a freeze dryer, avoiding manual interactions with vials.

Although operator intervention is regulated strictly, it still is the main source of contamination. IMA Life semi-automatic tray and fence loading/unloading system meets the highest industry standards for the aseptic operations, drastically reducing human intervention and minimizing contamination risks.

The semi-automatic loading and unloading system is very similar to our fully automatic system. The difference lies in the transport of the vials from the infeed/outfeed (un)loading system to the lyophilizer. As with the fully automatic system, the semi-automatic solution fills the gap between aseptic filling and capping operations. It is suitable for Cleanroom environments and pre-arranged for cRABS technologies.

- Loading speed up to 250 vials/minute.

- Semi-automatic operations.

- Excellent integration with Freeze Dryers, upstream and downstream machines.

PPS Service & Aftersales

Uniquely for the industry PPS has its own service department, which is of great benefit to our customers. PPS service department has specially trained technicians with the highest expertise and experience. We offer a long list of services, including:

- Installation and renovation of existing equipment.

- Design of complete solutions; everything from the requirements specifications and logistics, to execution and validation.

- Competent feedback on automation solutions or other type of production optimization.

- Installing and/or moving entire production or packaging lines.

- Training of technical personnel and operators in optimal use of the installed equipment.

- Tailor-made service and aftersales agreements for ongoing maintenance as well as assistance in case of breakdown.

In addition, PPS delivers spare parts and consumables directly to our customers from own stock. Having our own stock ensures fast and efficient delivery, which minimizes any production downtime for our customers.

If you want to know more about our service department, please contact us directly or get more information here.

IMA Liquid Filling Machines For Non-Sterile And Aseptic Fluids

Together with IMA, PPS supplies a number of different filling solutions for liquid substances, including for aseptic liquids.

The technology behind is suitable for cosmetic products, pharmaceuticals, nutraceuticals, and other food supplements. We offer the best suitable solution for filling liquids into ampoules, bottles, vials, syringes, capsules, or tubes. The filling equipment can be integrated into different packaging lines or other integrated solutions. Thereby you will benefit from the synergetic effects of integrating the entire packaging line.

Moreover, PPS supplies variuos high-perfomance solutions for washing or sterilizing bottles, ampoules, and other glass or plastic containers. Washing solutions include both linear and rotary washers, as well as customized solutions. Sterilization systems include moist heat sterilization, dry heat sterilization, and ethylene oxide sterilization (EtO). Besides the sterilization equipment itself process validation is required, including documentation of cycle repeatability and the functions of the sterilization system.

Do not hesitate to contact us to discuss the solution ideal for your production.

Liquid filling machines

PPS offers a range of solutions for filling various liquids into glass or plastic containers, making them ideal for pharmaceutical, cosmetic, or food applications. The filling machines can handle liquids of almost any viscosity and numerous container sizes and designs.

The high degree of automation optimizes the overall equipment effectiveness (OEE) of the liquid filling systems. The modular design and numerous configuration options present a solution that can be fitted to all customer specifications. Also, the filling machines can easily be combined with secondary packaging solutions.

- High quality liquid filling machines suitable for pharmaceuticals, nutraceuticals, other food applications, and cosmetic products.

- Compatible with a wide selection of closure types, such as spray pumps, droppers, pipettes, dosing cups, and different types of caps.

- All equipment is modular built and can be individually configured and precisely adapted to your specific requirements.

IMA EASYFILL Filling and stoppering machine

Designed to meet the requirements of the pharmaceutical industry in aseptic processing, EASYFILL is the right answer when a high degree of flexibility and modularity is required in sterile liquid filling.

Easyfill is a liquid filling and stoppering machine for vials, both small and large-volume parenterals, available in two models to satisfy medium and high-speed requirements.

The machine features a positive intermittent-motion, linear transport and brushless motors for precise movements. It can be equipped with all types of dosing systems typically used for aseptic products and with a checkweighing system composed of load cells for tare weight detection before filling and load cells for gross weight detection after dosing.

- No vial – no fill – no stoppering control device.

- Insertion of rubber stoppers for both liquid solutions and freeze-dried products.

- Suitable for integration with 100% In-Process Control.

Aseptic liquid filling machines

In addition to our filling equipment for non-sterile liquids, we also supply aseptic filling machines. All aseptic liquid filling machines from IMA guarantee excellent sterility assurance levels (SAL) and conforms to current Good Manufacturing Practice.

The aseptic filling systems offer efficient and reliable operation with high barrier protection. We offer first-class containment solutions to also protect the operator from any direct contact with toxic substances.

The aseptic filling machines can be configured as integrated solutions according to customer requirements, with selected upstream and downstream systems.

- Ideal for filling injection vials and infusion bottles for human and veterinarian medical applications.

- Closing station can be either integrated into the liquid filler machine or work as a line component. Compatible with different closure types.

- RABS (Restricted Access Barrier System), vertical laminated flow systems, and integrated CIP (Cleaning in Place) and SIP (Sterilization in Place) systems available.

IMA XTREMA High speed filling & stoppering machine

The main concern of the pharmaceutical packaging market has always been the integrity of the drug, and, in the case of parenteral dosage forms, its sterility. XTREMA indeed embodies the latest technological breakthrough in aseptic filling.

During the aseptic filling of dose containers with a drug, essential is preventing its contamination, thus minimizing its exposure to environment, equipment, manipulation from operators, etc., until its sealing.

XTREMA fundamental characteristics respond to the industry’s stringent technical requirements of vial filling, and with its flexible and ergonomic design it assures the most complete possibility to integrate modular equipment, and, why not, even to install multiple filling systems (liquids & powders) to be used alternatively within the same machine frame.

IMA SMART Filling, stoppering and capping machine

Time and ease of use are of the essence with small to medium batch production, but, with the SMART, IMA expertise realized something more: it combined proven simple technology with high standards of quality and reliability suitable to any aseptic filling need.

SMART is the answer to the increasing demand for even more flexible and versatile processing and packaging solutions. Short start-up times, easy changeovers and a high degree of automation are key considerations.

SMART can be equipped with all types of dosing systems typical of the aseptic operations, and it is suitable for installation in cleanroom or under isolator, being all materials compatible with sterilizing agents and suitable for VHP exposure.

Available machine versions: SVP and LVP, with or without integrated capping module.

- Suitable for small batch production with output up to 120/vpm in the double-index configuration

- Slim & smart pharm design, fit for each type of lay out, even when space constraint is an issue

- 100% check weighing of all filled vials

IMA LOADING SYSTEMS WITH TRAYS AND FENCES Semi-automatic vial loading & unloading systems

The aseptic production of pharmaceuticals usually takes place in cleanrooms in order to prevent contamination. IMA Life semi-automatic systems provide a controlled solution for loading fences in/out of a freeze dryer, avoiding manual interactions with vials.

PPS Service & Aftersales

Uniquely for the industry PPS has its own service department, which is of great benefit to our customers. PPS service department has specially trained technicians with the highest expertise and experience. We offer a long list of services, including:

- Installation and renovation of existing equipment.

- Design of complete solutions; everything from the requirements specifications and logistics, to execution and validation.

- Competent feedback on automation solutions or other type of production optimization.

- Installing and/or moving entire production or packaging lines.

- Training of technical personnel and operators in optimal use of the installed equipment.

- Tailor-made service and aftersales agreements for ongoing maintenance as well as assistance in case of breakdown.

In addition, PPS delivers spare parts and consumables directly to our customers from own stock. Having our own stock ensures fast and efficient delivery, which minimizes any production downtime for our customers.

If you want to know more about our service department, please contact us directly or get more information here.