Cobots, automation and robotic systems

PPS supplies a number of cobots, high-tech automation and robot solutions with equipment from e.g. Universal Robots and Denso.

Robotic systems can optimize your productivity and shorten your production lead times by, for example, ensuring higher precision and higher speed, or by automating repetitive or potentially unsafe/manual processes.

PPS offers customized solutions as well as standard automation and robot equipment. Please contact us for more information.

Collaborative robots: high-tech automation and optimization from Universal Robots

Collaborative robots—or cobots—are designed to share a workspace with humans and can either work autonomously or with limited assistance. They are cost-effective, safe, and flexible to deploy, making them an excellent choice for production optimization.

After an initial risk assessment, cobots can operate right next to human operators without the need for any safety guards. All collaborative robot arms offer easy programming, fast set-up and fast changeovers. This makes automation easier and more accessible than ever before for businesses of all sizes.

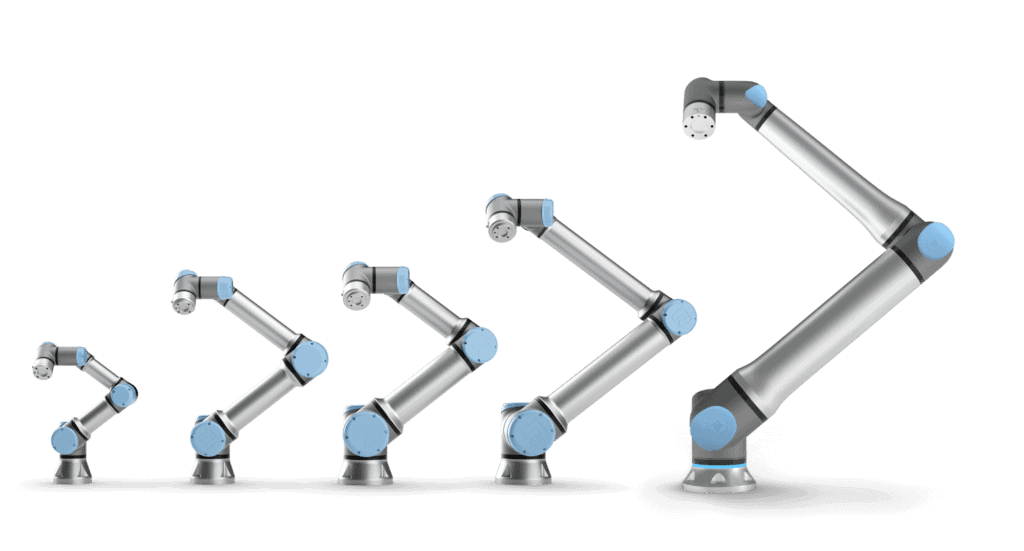

Universal Robots offer six different flexible cobot arms to assist with a wide range of applications in your production. The robot selection includes:

- UR3e: An ultralight, compact tabletop robot with a payload of 3 kg. It is ideal for applications where size, security and cost are critical.

- UR5e: A flexible lightweight robot arm with a payload of 5 kg, suitable for optimizing low-weight processes.

- UR10e: An extremely versatile collaborative industrial robot arm, with a payload of 12,5 kg and a range of 1300 mm. It is ideal for a wide range of applications in machine fitting, palletizing and packaging.

- UR16e: A powerful collaborative robot arm from UR, with an impressive payload of 16 kg. This powerful robotic arm can handle heavier tools and is ideal for handling heavy machinery, material handling, packaging as well as screw and nut tasks.

- UR20: The first industrial cobot in the next generation from Universal Robots. Designed to take performance to the next level. The UR20 has a range of 1750 mm and a payload of 20 kg

- UR30: The newest and so far, most powerful cobot from Universal Robots. With a payload of 30 kg and a range of 1300 mm, this cobot can handle bigger machines, palletize heavy products and effectively support high torgue screw work.

Advantages of cobots in the workspace

Cobots from Universal Robots are designed to make a difference by providing straightforward automation and optimization to your workspace. The many advantages of incorporating cobots into your production flow include:

- Delegation of routine work to cobots allows your employees to focus on more important tasks

- Fast and easy setup that significantly reduces deployment time

- Flexible automation, allowing you to re-deploy your cobots to multiple applications without changing your production layout

- Delegation of repetitive and hazardous tasks to cobots, reducing strain and limiting work-related injuries to your employees

Read more about cobots here.

Denso Robots: industrial robotic arms

Denso produces some of the world’s most advanced industrial robotic arms; four-axis robots (SCARAs), and five- and six-axis robots. The robotic solutions can be used in numerous production settings for a wide range of applications. We supply robot arms for floor, wall or ceiling mounting.

In our selection of Denso robotic arms, you will find:

- Industrial robot arms with sterility control for use in clean room environments available

- Robot arms for both small and restricted spaces as well as bigger workspaces with room for wide arm reach

- Powerful robotic arms with a maximum payload up to 20 kg

Maintain your cobot solutions with PPS service & aftersales

At PPS, we offer a long list of services, including:

- Installation, moving and renovation of existing cobots and automation equipment

- Expert feedback on robotic automation solutions and other types of production optimization

- Training of technical personnel and operators in optimal use of the cobots and robotic equipment

- Tailor-made service and aftersales agreements for ongoing cobot and automation maintenance as well as assistance in case of breakdown

- Delivery of spare parts and consumables directly to our customers from our own stock, minimizing any production downtime for our customers

If you want to know more about how our service department can help maintain your cobots and robotic systems, please contact us directly or get more information here.

Cobots, automation and robotic systems

PPS supplies a number of cobots, high-tech automation and robot solutions with equipment from e.g. Universal Robots and Denso.

Robotic systems can optimize your productivity and shorten your production lead times by, for example, ensuring higher precision and higher speed, or by automating repetitive or potentially unsafe/manual processes.

PPS offers customized solutions as well as standard automation and robot equipment. Please contact us for more information.

Collaborative robots: high-tech automation and optimization from Universal Robots

Collaborative robots—or cobots—are designed to share a workspace with humans and can either work autonomously or with limited assistance. They are cost-effective, safe, and flexible to deploy, making them an excellent choice for production optimization.

After an initial risk assessment, cobots can operate right next to human operators without the need for any safety guards. All collaborative robot arms offer easy programming, fast set-up and fast changeovers. This makes automation easier and more accessible than ever before for businesses of all sizes.

Universal Robots offer six different flexible cobot arms to assist with a wide range of applications in your production. The robot selection includes:

- UR3e: An ultralight, compact tabletop robot with a payload of 3 kg. The UR3e is an ideal cobot for applications where size, security and cost are critical.

- UR5e: A flexible lightweight robot arm with a payload of 5 kg. The UR5e cobot is suitable for optimizing low-weight processes.

- UR10e: An extremely versatile collaborative industrial robot arm, the UR10e has a payload of 12,5 kg and a range of 1300 mm. This cobot is ideal for a wide range of applications in machine fitting, palletizing and packaging.

- UR16e: The largest robot arm from UR, the UR16e has an impressive payload of 16 kg. This powerful robotic arm can handle heavier tools and is ideal for handling heavy machinery, material handling, packaging as well as screw and nut tasks.

- UR20: The first industrial cobot in the next generation from Universal Robots. Designed to take performance to the next level. The UR20 has a range of 1750 mm and a payload of 20 kg.

- UR30: The newest and so far, most powerful cobot from Universal Robots. With a payload of 30 kg and a range of 1300 mm, this cobot can handle bigger machines, palletize heavy products and effectively support high torgue screw work.

Advantages of cobots in the workspace

Cobots from Universal Robots are designed to make a difference by providing straightforward automation and optimization to your workspace. The many advantages of incorporating cobots into your production flow include:

- Delegation of routine work to cobots allows your employees to focus on more important tasks

- Fast and easy setup that significantly reduces deployment time

- Flexible automation, allowing you to re-deploy your cobots to multiple applications without changing your production layout

- Delegation of repetitive and hazardous tasks to cobots, reducing strain and limiting work-related injuries to your employees

Read more about cobots here.

Denso Robots: industrial robotic arms

Denso produces some of the world’s most advanced industrial robotic arms; four-axis robots (SCARAs), and five- and six-axis robots. The robotic solutions can be used in numerous production settings for a wide range of applications. We supply robot arms for floor, wall or ceiling mounting.

In our selection of Denso robotic arms, you will find:

- Industrial robot arms with sterility control for use in clean room environments available

- Robot arms for both small and restricted spaces as well as bigger workspaces with room for wide arm reach

- Powerful robotic arms with a maximum payload up to 20 kg

Maintain your cobot solutions with PPS service & aftersales

At PPS, we offer a long list of services, including:

- Installation, moving and renovation of existing cobots and automation equipment

- Expert feedback on robotic automation solutions and other types of production optimization

- Training of technical personnel and operators in optimal use of the cobots and robotic equipment

- Tailor-made service and aftersales agreements for ongoing cobot and automation maintenance as well as assistance in case of breakdown

- Delivery of spare parts and consumables directly to our customers from our own stock, minimizing any production downtime for our customers

If you want to know more about how our service department can help maintain your cobots and robotic systems, please contact us directly or get more information here.