Herma InNo-Liner Linerless Labeling System

Less waste. Less expense. Good for the environment.

Every year, more than 100 billion parcels are sent worldwide. The number is continuously rising, and practically all of them carry a shipping label. With a traditional, self-adhesive shipping label, a huge amount of waste is produced from the liner material. Millions of tons of waste are created around the world, solely from the liner material, that is completely useless once the labels have been applied.

The Herma InNo-Liner system is linerless and apply labels with the patented self-adhesive material. Due to the lack of liner and therefore the minimized waste, the Herma InNo-Liner is not only a cost-cutting game changer from the perspective of logistics and shipping, but also actively contributes to protecting the environment. In the absence of a liner, each roll can accommodate more labels, so that both the shipping weight and the necessary warehousing space are reduced.

Highly adhesive due to a special micro-atomizer

Although linerless applications already exist, including in the form of self-adhesive receipts or vouchers and sealing labels, their serious shortcomings have condemned them to a niche existence. Because these types are sticky from the outset and wound on rolls, their surface is often siliconized and therefore incompatible with printing inks – and thermal printers can produce only black or single-color lettering and images. Other systems, such as those that are activated by heat, suffer from inherent speed limitations.

No silicone is required for the Herma InNo-Liner system, as the activation of the self-adhesive material, only takes place during dispensing. The label is not sticky at all at first but becomes highly adhesive in a fraction of a second, as it is activated when dispensing, by a special micro-atomizer with demineralized water. With the restriction to siliconized thermal paper lifted, another major advantage lies in the diverse range of label materials that are available to users and label printers.

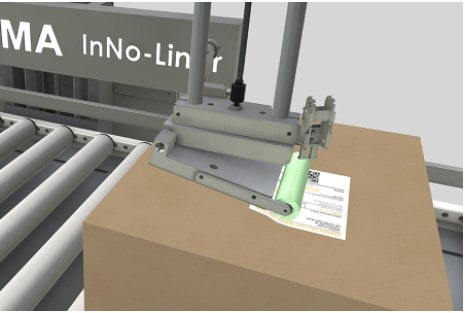

How the Herma InNo-Liner works

The Herma InNo-Liner system is characterized by the fact that the labels do not require a liner. The labels are wound on rolls and are not sticky because the adhesive is not activated until later. When the label is dispensed, the micro-atomizer activates the adhesive by applying a precise dose of demineralized water. The strength of the immediate, uniform, and tenacious adhesion enables the label to hold so fast that any attempt to detach it from the parcel inevitably tears fibres from the packaging material as well. Water consumption is minimal in the process, especially since any unused water is filtered and recycled in the system.

The Herma InNo-Liner system is equipped with sensor control for variable labeling heights and can therefore apply labels to the top of any boxes or shipping cases of different heights that are fed to the applicator in any sequence.

Technical details

If you wish to read more about the technical details on the Herma InNo-Liner, please download the leaflet on the button below. Please feel free to contact us if you have any questions.

Benefits of the Herma InNo-Liner

In the tabs below, we have listed the biggest benefits of the Herma InNo-Liner Linerless Labeling System, compared to both self-adhesive labels and siliconized linerless as well as the ecological benefits.

Herma InNo-Liner compared to self-adhesive labels:

- No liner waste and therefore no waste disposal

- More material on each roll and therefore fewer roll changes

- Less material consumption (no label feed or waste stripping)

- Avoidance of torn backing paper

- Variable label length

- Free from silicone

- Lower transport volume and weight and therefore reduced CO2 emissions

- Less warehousing space

Herma InNo-Liner compared to siliconized linerless:

- Highly diverse materials

- Multicolor printing possible

- Various printing techniques possible

- Free from silicone

- Permanent final adhesion

- Accelerated cycle speed

- Lower costs

- Cut edges do not stick to each other

- Reduced downtimes

Ecological benefits of the Herma InNo-Liner:

- No liner waste

- Lower transport weight

- Lower transport volume

- Reduced CO2 emissions

- Less material consumption (no label feed or waste stripping)

- Free from silicone

Wish to know more?

If you have any questions or wish to know more about the Herma InNo-Liner Linerless system, please feel free to call us or fill out the form below.